Silicio FerroSolar’s Technologies

Some of the technologies for silicon refining developed at Silicio FerroSolar are the

following ones:

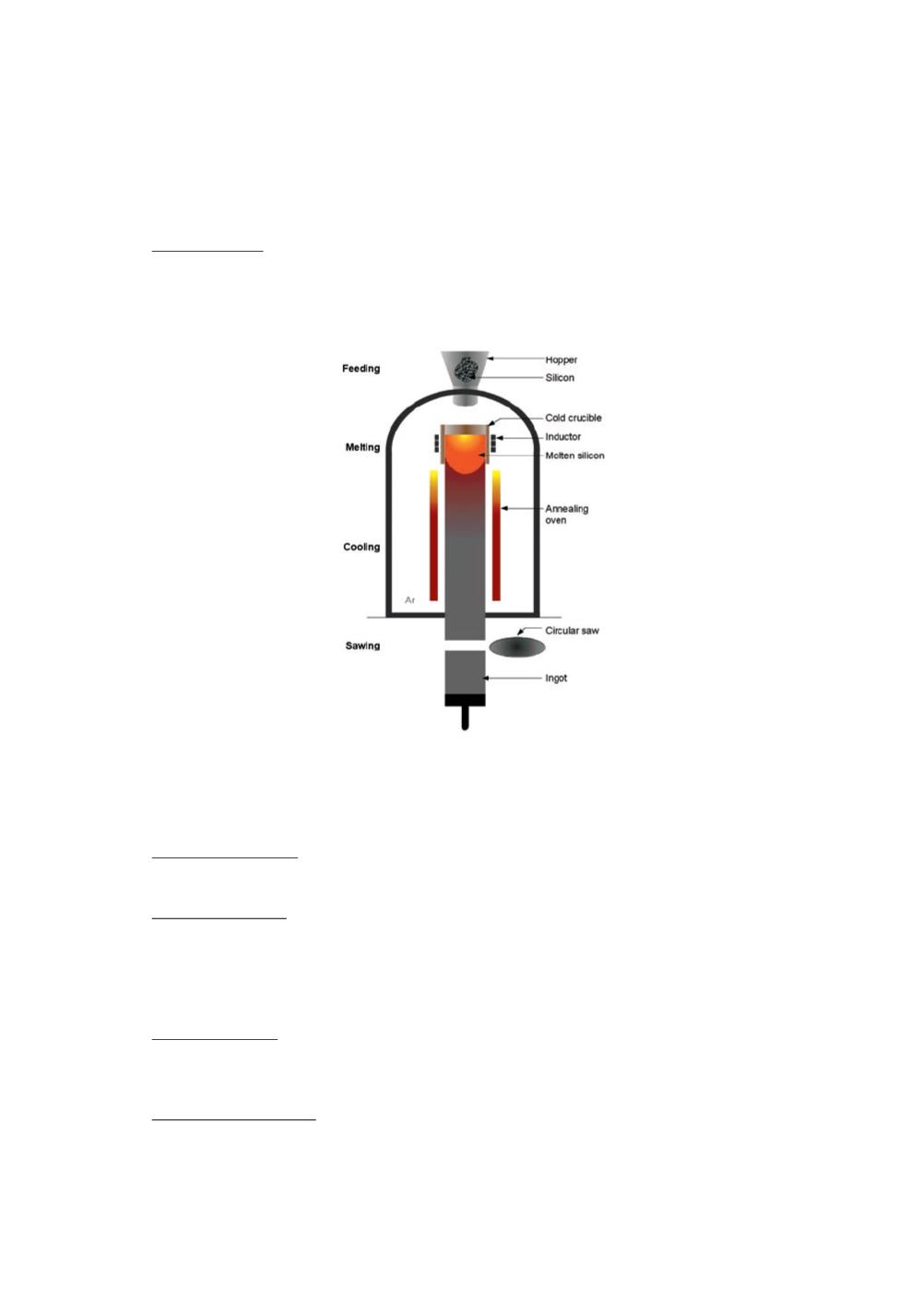

EMCC Furnace: In this furnace, silicon is charged in a cold crucible with an induction

coil which melts silicon creating a silicon bath which is vigorously stirred by the

electromagnetic forces. Then the silicon bath is fed continuously and the pulling begins.

It is a very clean process, because there is not hot crucible and the stirring effect could

help to remove inclusions, including silicon carbide inclusions.

&ŝŐƵƌĞ ϭ

͘

D ƚĞĐŚŶŶŽůŽŐLJ

For this reason, is a very suitable technology for recycling top cuts from PV Industry

Segregation Furnaces: we have developed segregation furnaces that allow us to reduce

the metallic impurities content and to produce 3N-6N silicon quality.

Induction Furnaces: in the Induction Furnaces we carry out slagging processes to reduce

all the impurities whose oxides are more stable than silicon, namely Boron, Aluminum,

Calcium, etc. This is especially useful for the Boron reduction for the production of 3N

to 6N material. In these furnaces we could also remelt silicon fines, e.g. kerf from wafer

slicing.

Vacuum furnaces: by refining silicon in vacuum atmosphere we are able to remove

phosphorus, aluminum, calcium and oxygen. The main application of this furnace is for

6N material and when it is required silicon without oxygen.

Crushing and grinding: we work with state of the art materials to avoid the silicon

pollution during crushing and grinding. We are capable to obtain also smaller particles

(less than 100 microns) without contamination of silicon during processing.

21