3SiO(g) + CO(g) = 2SiO

2

(s,l)+ SiC(s)

∆

H

o

1500

o

C

= -1380 kJ/mol

(4)

SiC (s) + SiO (g) = 2 Si(l) + CO (g)

∆

H

o

2000

o

C

= 167 kJ/mol (5)

SiO

2

(l) + Si(l) = 2SiO (g)

∆

H

o

2000

o

C

= 599 kJ/mol (6)

2SiO

2

(s,l) + SiC (s) = 3SiO (g) + CO (g)

∆

H

o

2000

o

C

= 1364 kJ/mol (7)

The final product: Silicon is produced by reaction (5) at temperatures above 1811

0

C.

The gas in the Si-furnace is a mixture of CO and SiO at 1 atm. pressure. To produce

Si at 1811

0

C by reaction (5), partial pressure of SiO must be higher than 0.67 [2]. To

achieve a high Silicon yield, SiO-gas should preferably be produced at temperatures

above 1811

o

C. For reactions with quartz, reaction (6) and (7) a slow reaction rate at

low temperatures is thus preferable.

SiO produced at lower temperatures than 1811

o

C, e.g. higher up in the furnace may

either react with carbon to SiC by reaction (2), be captured in the furnace by reaction

(3) and (4) or leave the furnace with the off-gas. Reaction (3) and (4) are highly

exothermic. A surplus of SiO produced in the lower part of the furnace that condenses

in the upper part will thus transport energy to increase the temperature in the upper

part of the furnace.

To achieve a high silicon yield, the SiO gas must not leave the furnace with the off-

gas, but react according to reactions (2), (3) or (4). The reaction products from (3) and

(4), the "condensates" are sticky, will glue the charge materials together and hinder

material and gas flow in the furnace. Gas flow and permeability in Si-furnaces are

believed to be more affected by condensates than by amount of fines and size

distribution. At 1726

o

C. SiO

2

melts to viscous fluid that will also affect material and

gas flow as well as reaction rates. Softening of SiO

2

particles giving a semi--molten

surface that start before they reach the melting temperature will also reduce gas

permeability and reaction rates.

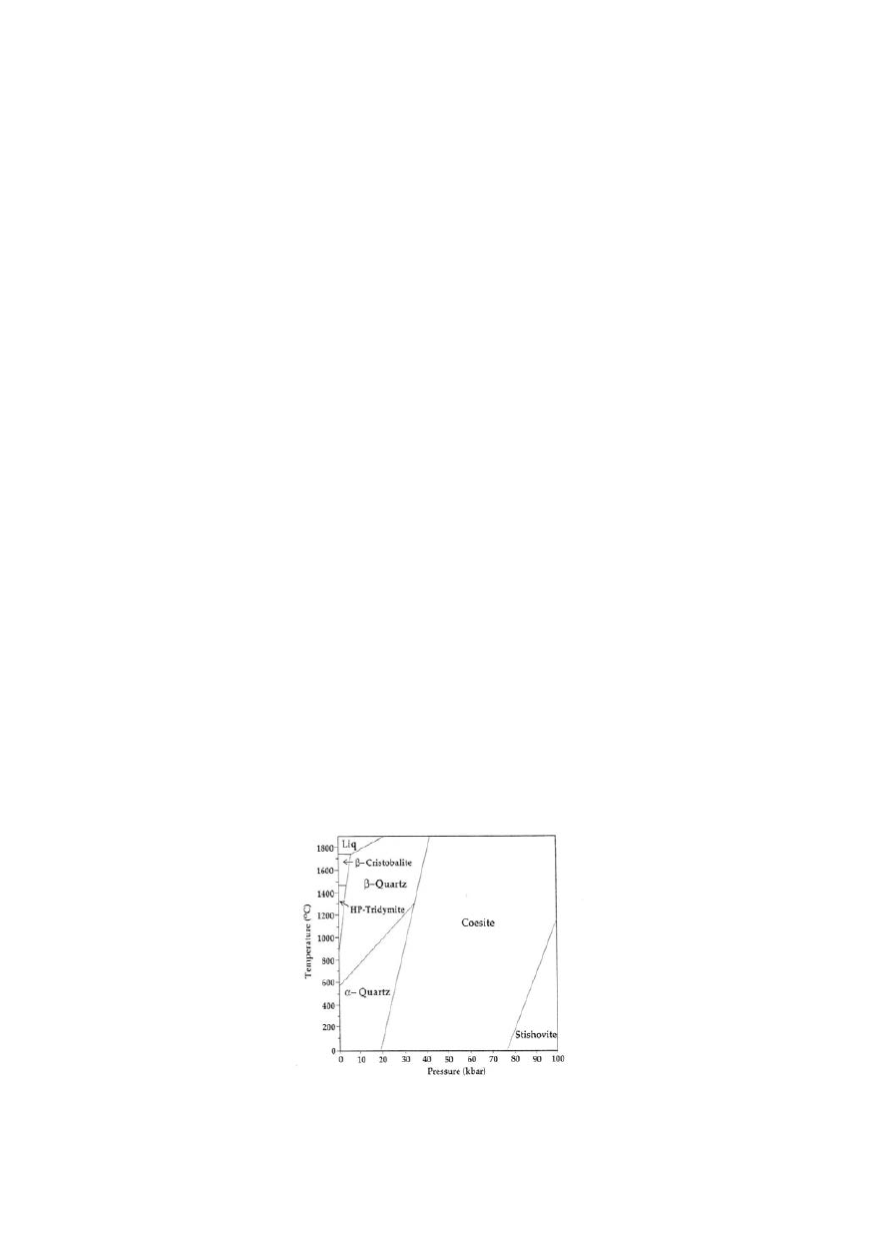

Phase transformation in quartz

When quartz is heated, its structure will change to different SiO

2

polymorphs as

shown in the phase diagram in Figure 2 [6].

Figure 2. SiO

2

phase diagram [6]

271