11

Background

Multistage centrifugal pumps with diffuser vanes are used in

the oil industry to pump produced water, i.e. water which is

separated from the oil. The produced water contains salt water

with small oil droplets. Because of environmental regulations,

the oil droplets need to be separated from the produced water

before the water is released back into the sea. The efficiency

of the separation process is dependent on the size of the oil

droplets. It is therefore desired to obtain the optimal size.

The pumps that are used today has a tendency of making

the droplets smaller. A company in Stavanger, Norway named

Typhonix is researching on a multistage centrifugal pump

which under certain operating conditions is able to enlarge the

oil droplets. The increase in droplet size increases the energy

efficiency of the separation process compared to the traditional

pumps.

This thesis is a continuation of the work done in my project

thesis. A test rig for the centrifugal pump has been built in the

Waterpower laboratory. The flow characteristics in the diffuser

of the pump will be investigated further and more thoroughly,

providing PhD. candidate Alessandro Nocente with experimental

data. The equipment used for measuring the velocity is Laser

Doppler Velocimetry (LDV). This data will be compared with a CFD

simulation performed in Fluent to possibly verify the numerical

model.

In addition a mesh sensitivity analysis of the numerical model

will be performed. The mesh will be modified by using Ansys

ICEM. Also, the solution from Fluent will be compared with a

OpenFOAM solution.

Supervisor: Torbjørn K. Nielsen

Co-supervisor: Alessandro Nocente

By Karl Oskar Pires Bjørgen

Master Thesis

Waterpower Laboratory

LDV Measurements in

Centrifugal Pump Diffuser

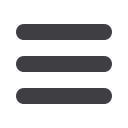

The diffuser of the test rig

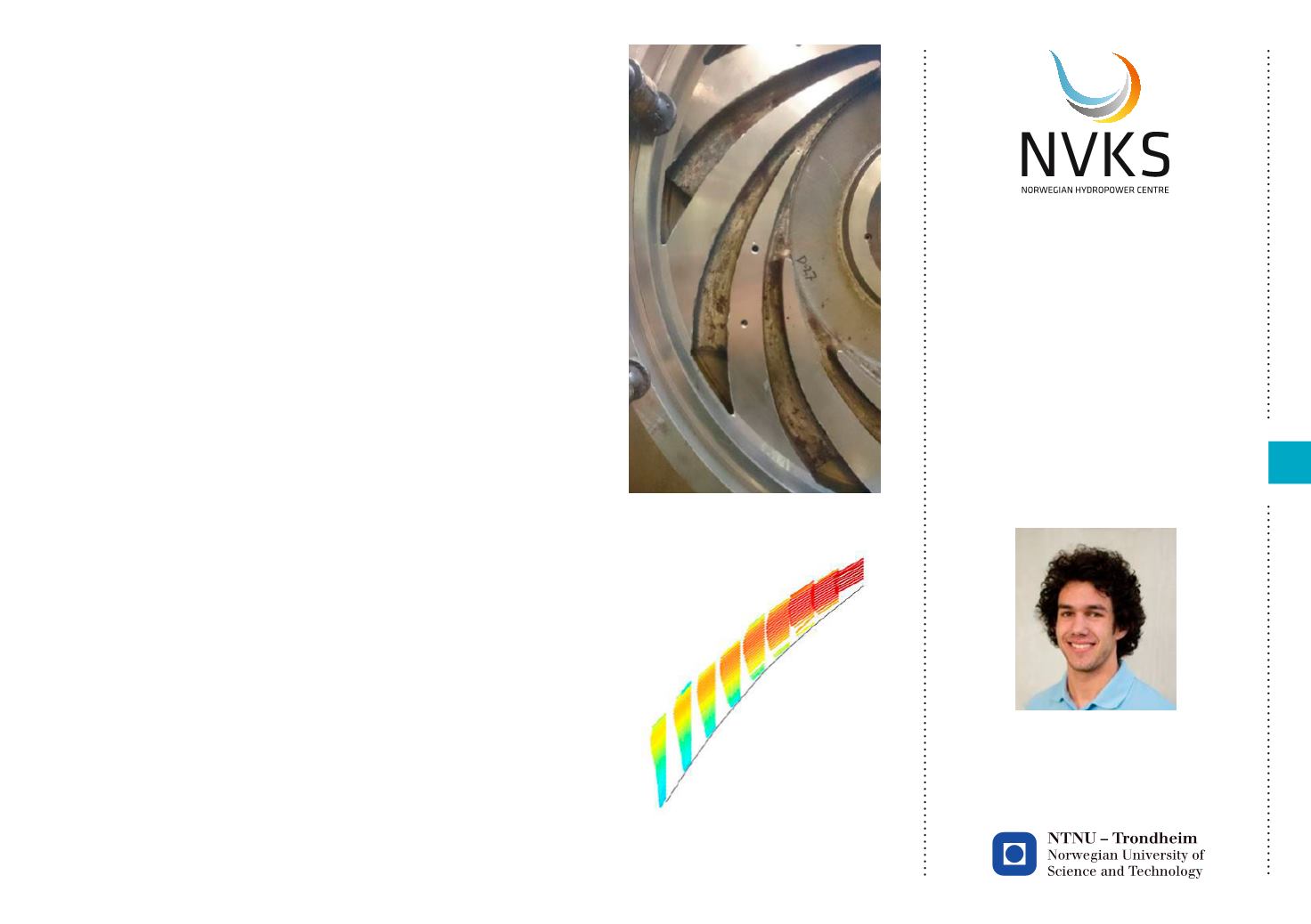

Velocity field of the diffuser,

results from the project thesis