19

technology tRansFeR

Methods and Tools

Heads of Programme: Odd-Geir Lademo and Térence Coudert

The Methods and Tools Programme represents the main

instrument to link

Basic research

at the Centre to Industrial

implementation at the industrial partners. The SIMLab Toolbox

is a synthesis of the research results. It supports and guides

the user to the necessary steps to build a reliable finite element

model for advanced structural analysis, such as selecting

the suitable material model, processing experimental data,

calibrating and optimizing the material model parameters.

Two main tasks have been performed during 2016. One was to

improve the existing SIMLab Toolbox and the other, in close

collaboration with the Metallic Materials Programme, was to

develop and introduce new tools for multiscale modelling.

Components in the SIMLab Model Library (SML) have been

released for the partners: SMM for Metals and SPM for

Polymers. Other developments have been carried out for

the SCMM (Crystal Mechanics), the SCZM (Cohesive Zone)

and for the SPPM (Porous Plasticity) and some of them will

be released in 2017. The development work is performed in

a professional software development arena ’

code.sintef.no’

,which enables team-oriented development through proper

systems for documentation, version control, issue tracking,

and continuous feature testing. Using the latter, the SMM

and SCMM are tested against well-known simulation cases

in an automated procedure using LS DYNA and ABAQUS. This

enables the developer to raise issues early when a change is

made in the user material subroutine. The model calibration

toolbox (e.g. MatPrePost) provides identification procedures

for the SMM and the SPM. As other material models could be

supported in the near future (e.g. Johnson-Cook model), the

development of a material card converter has been initiated.

Several tools are needed at different scales to assist the

research in the various programmes. In 2016, focus has

been given to generating representative volume elements

for FEA using the Crystal Mechanics model. The team has

selected an open source software DREAM.3D and developed

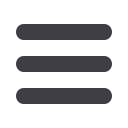

plugins that fit the needs of the Centre. As shown in Figure

11, DREAM.3D is modular software package that allows

users to reconstruct, instantiate, quantify, mesh, handle and

visualize multidimensional, multimodal data. It was originally

designed to analyse microstructure data coming from EBSD

observations, and can generate equivalent material structures

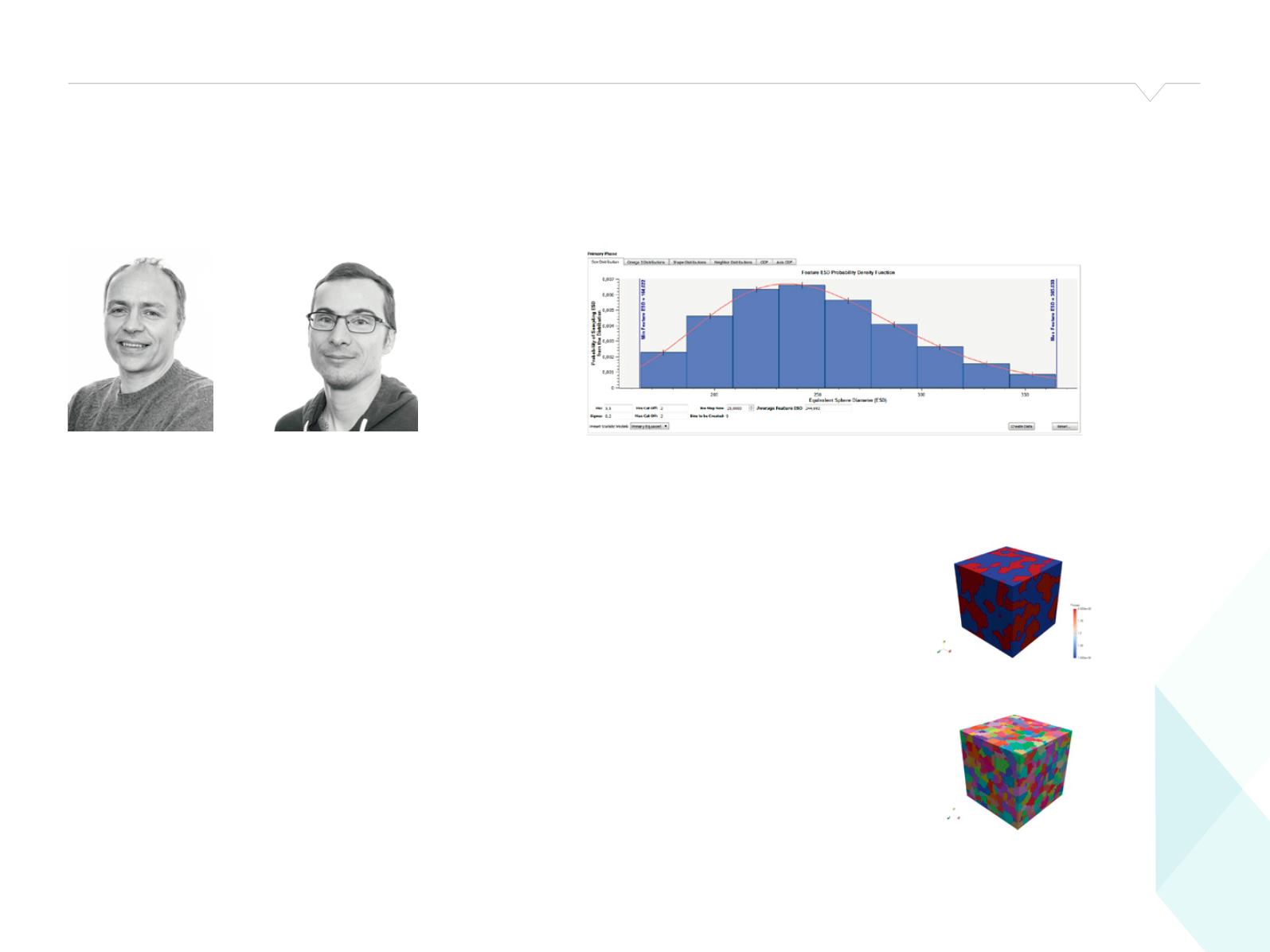

(as shown in Figure 12) from statistics that are synthetic or

are extracted from real data. A series of filters have been

developed to allow the generation of 3D hexa-based and 2D

shell-based meshes, with corresponding material cards for the

SCMM. The generated input files are for LS DYNA or ABAQUS.

During a multiscale modelling approach, several solvers and

data sets are used. Since the solvers may run on different

platforms and a variety of machines, the development team

has tried to find a solution to obtain an efficient mechanism

for storing and exchanging data. This problem is well-known in

software development and some solutions already exist (e.g.

SOFT5 in EU project NanoSim).

Figure 11: DREAM.3D software: plugin interface to control the grain distribution.

Figure 12: Example of

generated microstructure.

TECHNOLOGY TRANSFER