14

ReseaRch PRogRammes

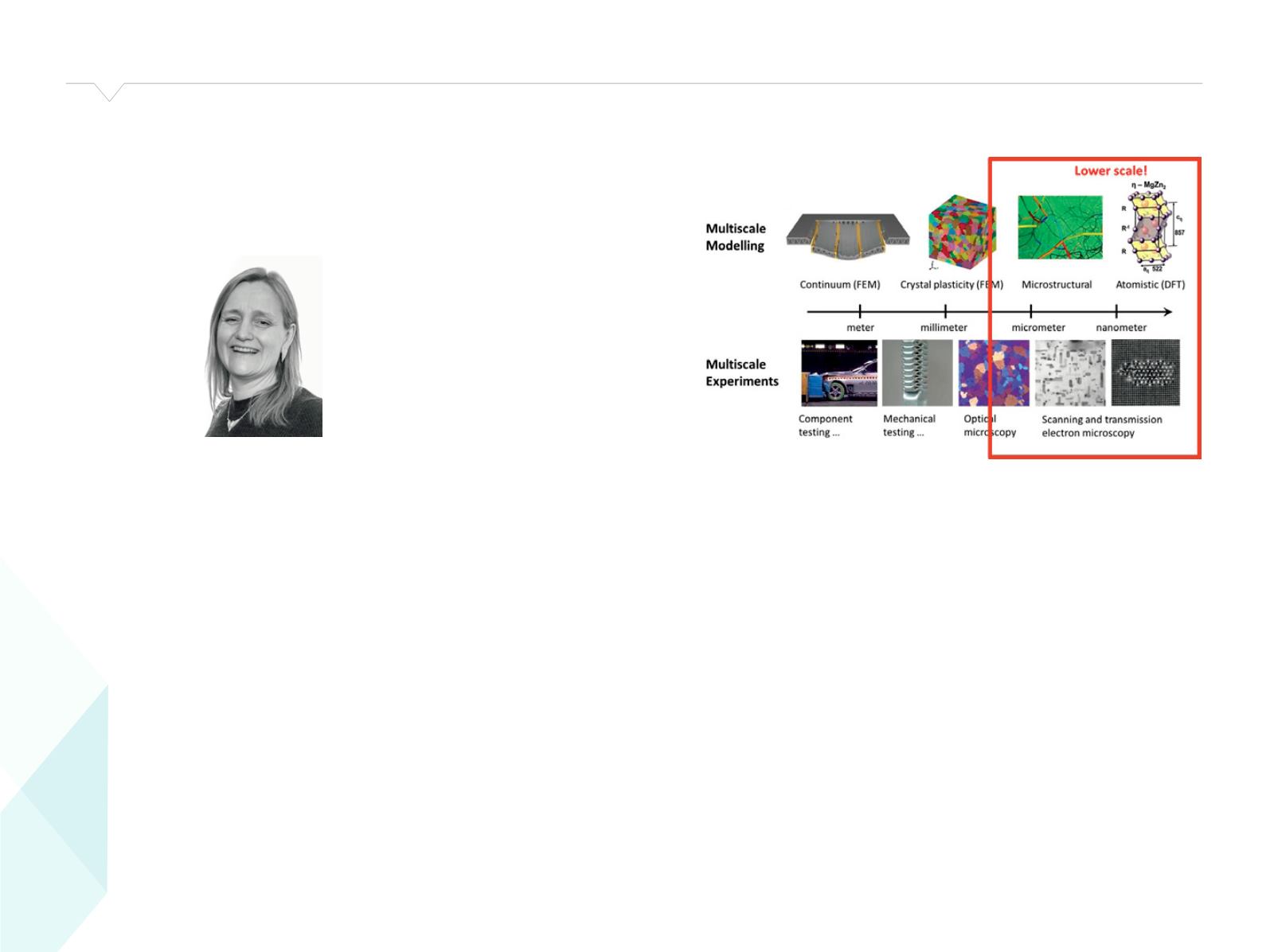

This programme concentrates on the lower length scales

of materials, from the atomic up to micrometre scale.

Thus, it will provide experimental and calculated input to

the multiscale framework from the lower scale. This will

provide constitutive models for microstructure evolution,

strength and work hardening for metallic materials, such

as aluminium and steels. It will also provide a foundation

for the development of physically based models for crystal

plasticity, continuum plasticity, damage and fracture.

The overall goal is to connect and coordinate the atomic

and microscale frameworks connecting the models and

the experiments at the different scales. The results will

provide increased basic understanding of mechanical

properties and deformation of metal structures in a

multiscale framework (from the nano-scale to the

complete structure). This will work as a basis for

achieving improved models and will be used in both

model developments and validations, Figure 4.

Four PhD students are working in the lower scale

programme:

• PhD research by Emil Christiansen (Dept. of Physics,

2015-2019) is focused on the micro- and nanostructure

characterization of deformed aluminium alloys using

transmission electron microscopy (TEM). The objective

is to investigate the underlying physical mechanisms of

ductile fracture in age hardening aluminium alloys. In

short, this PhD work is concerned with the interaction

between dislocations and precipitation free zones (PFZs)

and the evolvement of the microstructure as a function

of strain. So far, he has studied how the microstructure

in the PFZ of the AA6060 alloy changes as a function of

deformation. His results will act as input to the different

models used to describe deformation response and will

be applied to verify and develop numerical models in the

related SFI CASA projects.

• PhD student Christian Oen Paulsen (Dept. of Materials

Science and Engineering, 2015–2019) is focusing

his research on combining experimental work and

modelling activities to describe the correlation between

microstructure and mechanical properties in multiphase

steel. He is performing a systematic, experimental study

of local mechanical properties and in-situ testing using

scanning electron microscopy (SEM), with the possibility

of cooling the material to sub-zero temperatures.

This gives input data for mathematical models for

understanding and describing the performance of

heterogeneous materials based on microstructure

information. The experimental tests are combined with

digital image correlation to obtain detailed information

about the local deformation.

• The PhD project of Jonas Frafjord (Dept. of Physics,

2016-2020) will couple atomistic simulations, e.g.

density functional theory, and meso-scale methods,

e.g. dislocation dynamics. The goal is to provide a more

fundamental understanding of mechanical properties

and use this to improve and calibrate models on a

continuum scale. He will study the effect of solute

atoms and hardening precipitates, and how these

affect initial yielding and hardening under different

conditions. Initially, Jonas has started to study how

solute-dislocation interactions affect the yield stress

and he is developing a method that predicts from first

principle the influence of hydrostatic pressure on the

solute strengthening of various alloying elements (such

as Mg, Si, Fe and Mn) in aluminium.

• PhD student Jianbin Xu (Dept. of Materials Science

and Engineering, 2016-2019) is studying the Portevin–

Le Chatelier (PLC) effect, which describes the serrated

yielding some materials exhibit as they undergo plastic

deformation, resulting in early shear failure and thus

reduced formability. The effect is associated with

dynamic strain aging or interaction between solute

atoms and matrix dislocations in strained metallic

alloys. Initially, Jianbin has started to familiarize himself

with existing modelling approaches for work hardening

and flow stress to describe solid solution strengthening

and the PLC effect in aluminium alloys. He will continue

with experimental characterization to provide a basis for

testing, validation and further improvement of existing

modelling tools.

Lower Scale

Head of Programme: Randi Holmestad

Figure 4: In a multiscale framework, the lower scale

programme covers the micrometre and nanometre

scales for modelling and experiments.

RESEARCH PROGRAMMES