17

ReseaRch PRogRammes

The need for multi-material structures in the automotive,

offshore and physical security industries is becoming

increasingly important to meet the requirements in terms of

performance and weight reduction of their products. Often, the

behaviour of a structure is strongly linked to its connections

and its capacity to sustain and transfer the applied load to its

different members. In this perspective, the design of multi-

material structures using numerical simulations has to take

into account how the connections will behave and fail. Today,

large shell elements are used for computational efficiency

which hampers an accurate representation of the connections

and their failure modes due to a poor discretization of these

complex problems.

The aim of this research programme is to provide macroscopic

models for multi-material connections which are based on

a fundamental understanding of the structural joints. These

models should be industry-friendly in terms of computational

time as well as the calibration cost. Here, multi-material

connections involve a combination of aluminium, steel and

fibre reinforced polymers.

The objective of the programme is fulfilled by using a

multiscale testing and modelling strategy. This strategy

involves testing at different scales from the material within

the connector, through single connector tests, to the final

component level. Each of these testing levels is important

to gain a fundamental understanding of the connections of

interest. In terms of numerical modelling, mesoscopic models

where the connections are represented by solid elements

will be employed to increase knowledge of the behaviour and

failure of structural joints. However, macroscopic models are

the final outcome of the programme.

In 2016, a PhD project was launched with the PhD candidate

Matthias Reil, who is funded by BMW and CASA. The topic of

his work is joining of steel and aluminium using structural

bonding and self-piercing rivets. His project will have strong

focus on the virtual testing of these connections and the

calibration of industry-friendly macroscopic models.

Moreover, three other PhD students were involved in the

research programme in 2016:

• Johan Kolstø Sønstabø is working on the behaviour and

modelling of Flow-Drill Screw connections in aluminium

structures. (Funded by Honda Americas, started in 2013.)

• Erik Løhre Grimsmo is working on the behaviour and

modelling of bolted and welded connections. (Funded by SFI

SIMLab, started in 2013.)

• John Fredrick Berntsen is working on the behaviour and

modelling of multi-material connections. (Funded by SFI

CASA, started in 2015.)

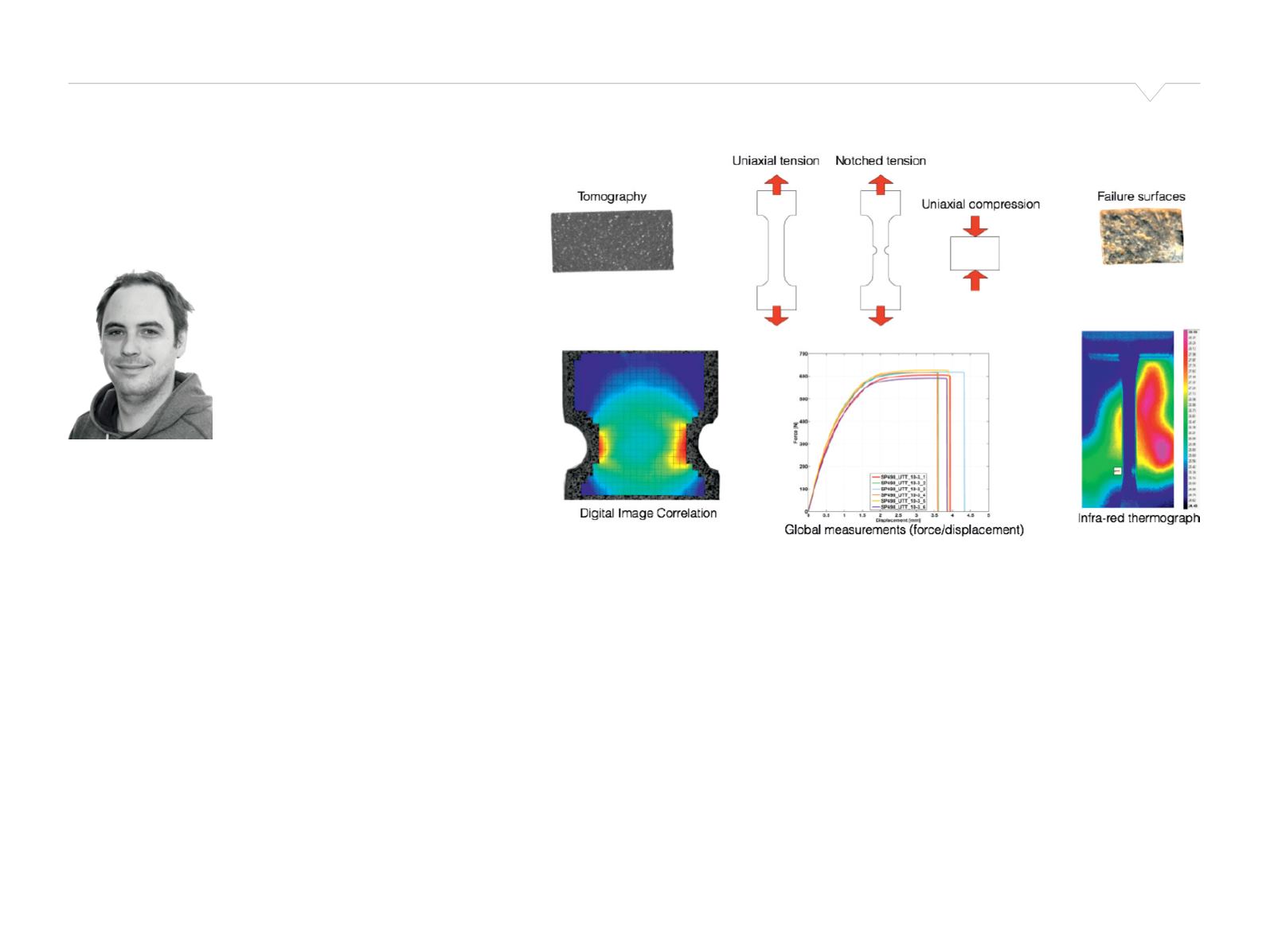

In 2016, PhD candidates Matthias Reil and John Fredrick

Berntsen characterized their respective structural adhesives

using the same procedure as that developed by the Polymeric

Materials research programme, Figure 8. During the spring

2016, PhD candidate Johan Kolstø Sønstabø spent three

months at Honda R&D Americas to implement some of the

results from his PhD into an industrial environment.

Structural Joints

Head of Programme: David Morin

Figure 8: Characterization

procedure of structural adhesives.