16

Research Programmes

Polymers comprise a wide range of natural and synthetic

materials. The demand for polymers has increased

considerably during the last few decades. Applications include

safety-related parts in cars, coatings, thermal insulation in

offshore components, seals and inter-glass layers in laminated

windows. The finite element method has only rather recently

become a relevant tool in the design process of parts made

of polymers. Therefore, constitutive models for such materials

are less mature than for metals. Prediction of fracture is also

a topic of interest for research and industry. Knowledge about

the physical mechanisms governing the thermo-mechanical

behaviour is of utmost importance for successful development

of material models. The main objective of the Polymeric

Materials research programme is to develop and improve

material models representing the thermo-mechanical response

up to fracture for polymers. The models will be developed for

application in an industrial context. Particular attention is paid

to validation and efficient identification of the parameters

involved in the models. Actual materials include commodity

thermoplastics (like PE and PP, commonly reinforced with

small mineral and/or rubber particles), fibre-reinforced

thermoplastics, elastomers and foams made of polymers.

The large-strain response of ductile thermoplastics has been

the topic of Marius Andersen’s PhD project. He finished his

thesis in early 2016. It contains work on the development

of robust methods for experimental characterization as well

as a constitutive model that is able to represent the stress-

strain curve at different strain rates and temperatures.

Directly financed by Aker Solutions in an affiliated project,

Arne Ilseng also delivered his PhD thesis in 2016. His topic

was the behaviour of elastomers at different temperatures.

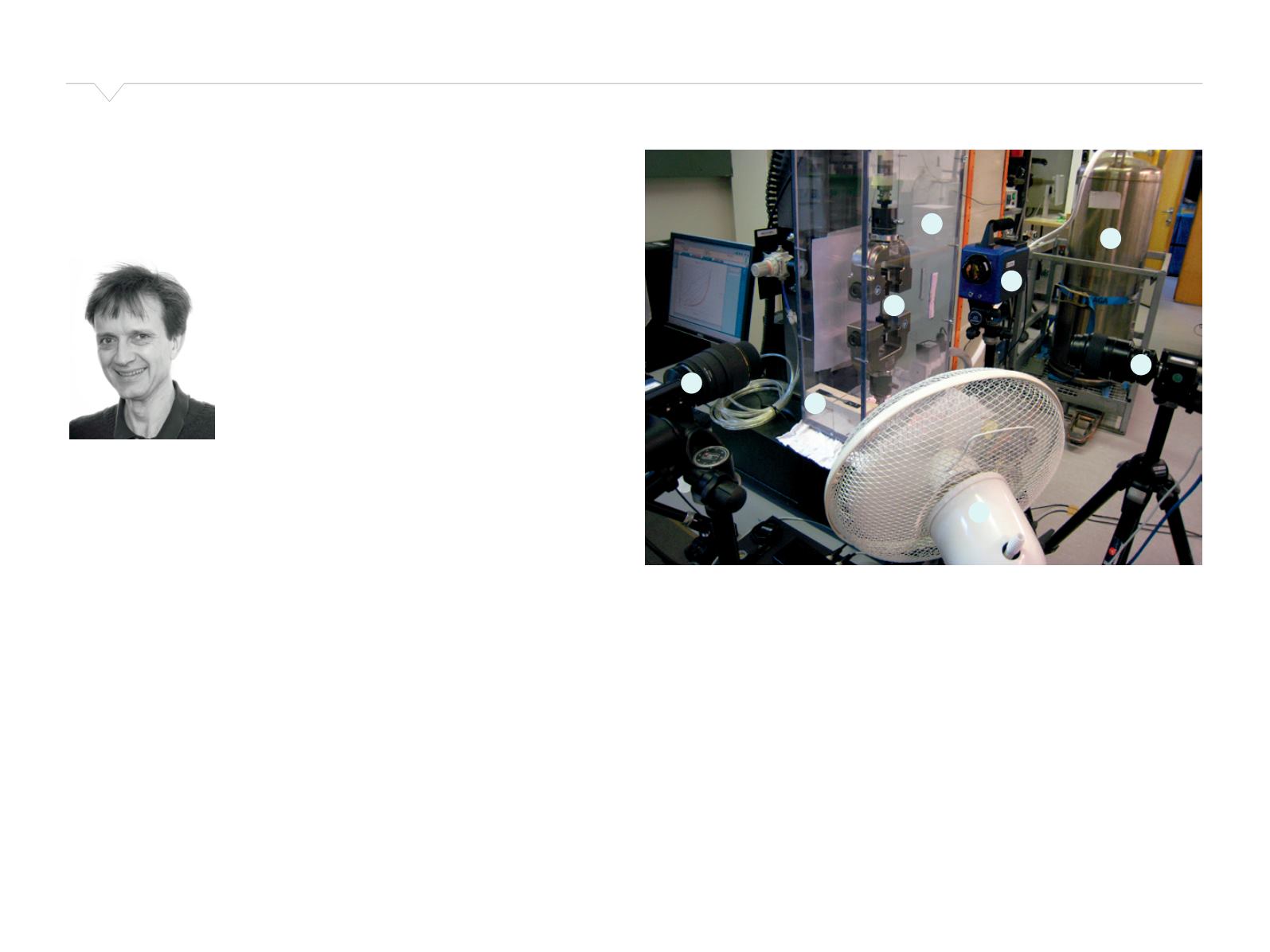

He applied a transparent chamber made of polycarbonate, see

Figure 7, in his research. It was connected to a supply of liquid

nitrogen, allowing for material testing at low temperatures in

combination with instrumentation involving digital cameras.

This chamber has also been applied in other studies.

Ongoing PhD projects comprise Petter Henrik Holmstrøm who

is working on the modelling of fibre-reinforced thermoplastics,

and Sindre Olufsen, who is studying ductile failure. In

addition to mechanical tests, computer tomography (CT)

is an important tool in both projects in order to improve the

understanding of the deformation mechanisms to capture

in the material models. New PhD candidates from August

2016 are Jon Eide Pettersen and Daniel Morton, who are

respectively working on viscoelastic behaviour and foams.

The interaction with the industrial partners engaged in the

Polymeric Materials programme is maintained through annual

technical meetings. One such meeting was arranged in

Trondheim in November 2016, and gathered Audi, BMW, DNV

GL, Statoil and Toyota. The partners addressed their research

needs at these meetings, and provided valuable advice for

future research activities.

Figure 7: Experimental set-up for material tests at low temperatures.

Polymeric Materials

Head of Programme: Arild Holm Clausen

1. Specimen

n

2. Specimen

n

+1

3. Camera 1

4. Camera 2

5. IR camera

6. LN2 container

7. PC chamber

8. Table top fan

7

8

1

2

3

4

6

5