20

technology tRansFeR

Industrial Implementation

Head of Programme: Magnus Langseth

In order to strengthen the industrial implementation of the

research and cooperation between the partners, an industrial

reference group has been established where there is one expert

from each partner. The mandate of the industrial reference

group states that an annual report has to be presented to the

SFI CASA Board about how the implementation is carried out.

A survey has been completed to facilitate the interaction

between the research group and the partners with respect

to implementation. The partners were asked to define what

implementation means, how implementation was carried out

and how the partners disseminated the obtained results in their

own organization. In addition, the partners have been asked to

define what is within and beyond the scope of the Centre and

how they define the characterists of an active partner or a

partner who only follows the research activities.

The answers from the partners show that implementation

is defined as short- and long-term activities. In a short-term

perspective, a key issue is the training of the partners to use

the tools that are developed, whereas for long-term activities

they expect that the technology will be implemented into their

daily processes. Implementation in such processes means for

instance that the models developed are incorporated into the

commercial solvers used by the partners and that the models

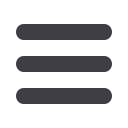

are robust, accurate, user friendly and well documented. Figure

13 illustrates how Audi plan the implementation of the SIMLab

Tool Box in their organization and how this is coupled with a

validation strategy.

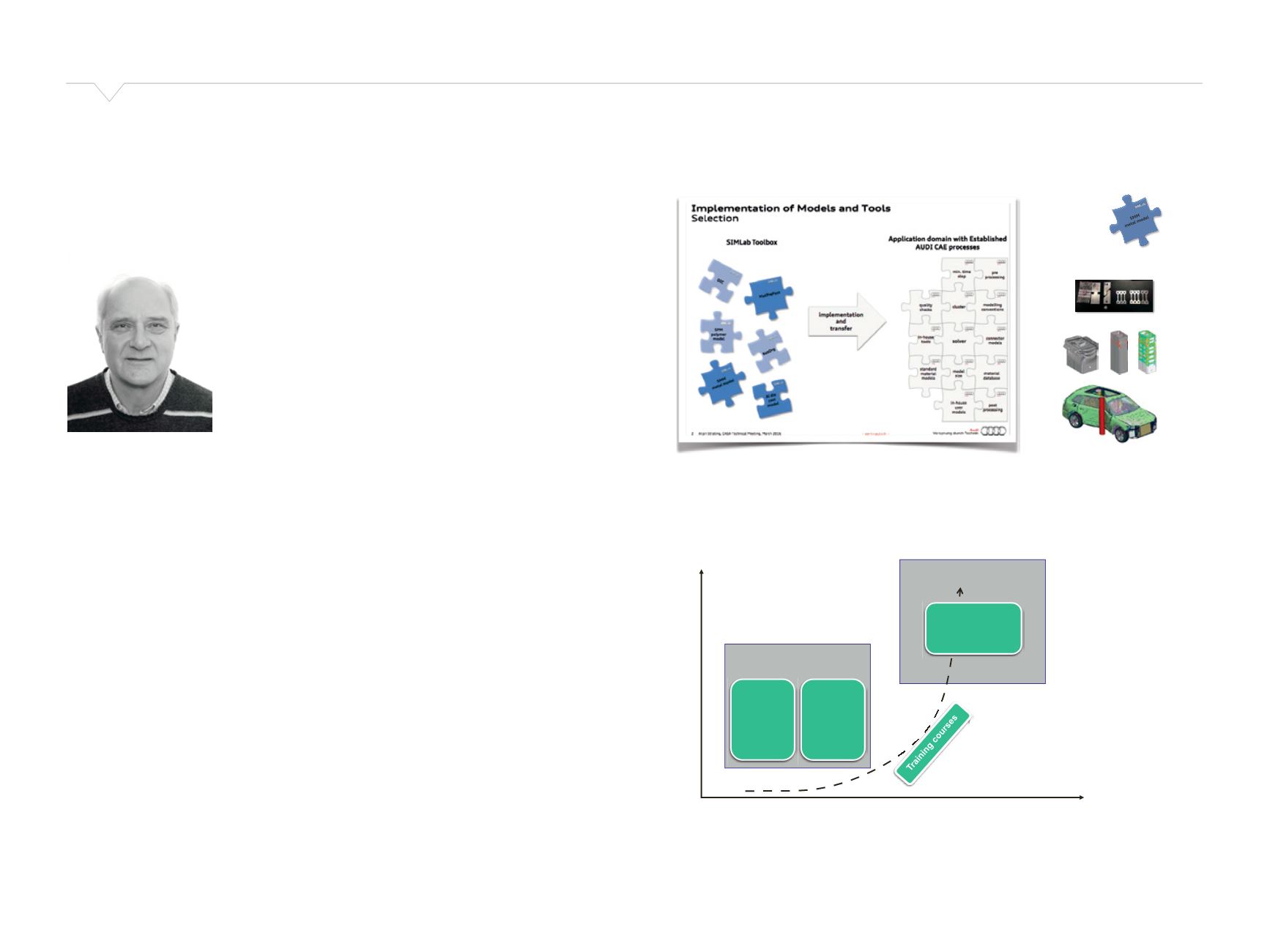

Figure 14 shows that all implementation in the Centre starts

with the proof of technology through master’s projects at NTNU

linked to the Centre’s activities. The partners launch the topic of

the master’s projects through the industrial reference group. At

a later stage, an internal evaluation of the technology is carried

out by the partners hosting master’s students. PhD candidates

can also contribute here. The proof of technology and the

internal evaluation are within the scope of the Centre, whereas

concurrent projects are outside. Figure 14 also illustrates that

all implementation is followed by training courses at NTNU or at

the partners. These courses are linked to a validation strategy

on several scales.

Figure 13: Implementation at Audi.

Figure 14: Proof of technology, internal evaluation and concurrent projects.

1

Master‘s

students

at NTNU

Master‘s

and

PhD

students

at the partners

Outside SFI-CASA

Interest of the partners

Time

Concurrent

Projects

Proof of

technology

Internal

evaluation

Inside SFI-CASA

2

Material

Component

Product

1

- vertraulich -

I m p l e m e n t at io n o f M o d e l s an d To o l s

P h a s e 3 : V a lid a t io n a n d A s s e s s m e n t

Main task:

►

Assessment of model qualities and limitations.

►

Find suitable model configurations for the application domain at

Audi.

►

Time window: 2013 - 2015

Main activities:

►

Validation activity on coupon and single part level.

►

Internship master student.

►

Application in full vehicle simulations to asses simulation cost and

model capabilities.

►

Cooperation with engineering partner.

NB. It is not a plug and play activity!

►

New questions and challenges will pop up along the way.

Arjan Strating, CASA-TechnicalMeeting,March 2016