129

systems & ProfIles

shingles can be put into different systems and patterns. the

decision of which system to use is often based on two factors:

function and aesthetics.

function meaning that the shingles need a system that will

allow them to dry out quickly to avoid rot and fungus. there are

different systems for different weather conditions. the oblique

overlapping system (ex.3) is made for more windy weather

conditions. the overlapping top should face the direction where

the wind normally comes from in order for the water not to run

into the overlapping part. this system can also be regulated to

how much you want to air it out. In the pictures it is the least

amount of air going through, in the picture from røros (lower

left) there is maximum air going through.

on the other hand, when considering how to best dry out

shingles the length of the shingle is more important than the

thickness. this because the wood mainly dries through its

fibers vertically (like straws), not across its fiber direction.

When it comes to aesthetics it’s just important to be aware of

what different expressions the different shingle-systems give.

We could also choose to cut the end of the shingles differently

to give it a more dynamic feel.

our consIderatIons

We chose to use a system that overlaps every second shingle

and every second batton (ex.1). this system supplies plenty

of air to dry shingles, but also uses more batton material.

our shingles are 12mm thick, which is quite thin for sawn

shingles. they are 150mm wide and 400mm long. We think

this combination of system and shingle profile gives a good

expression on our structure because we have such a massive

wall. many other shingle projects from earlier times have

smaller shingles, but are also more petite. scaling up the

shingle size seemed to fit the scale of our 5x5 meter cube.

the treatment of our shingles is somewhat more unorthodox.

Inspired by the traditional japanese technique shou suge Ban,

we decided to burn our shingles. the technique was devised as

a way to make wood less susceptible to fire, water and to keep

away insects, rot and mould. the alkaline environment in the

char keeps the bugs and microorganisms from thriving there.

the outer sapwood is burned , so water doesn’t draw in as

easily. since both shingle sides would be exposed we decided to

burn both sides of aestherical reasons.

the shingles are also treated with linseed oil to fill the wood

cell fibres, so it doesn’t draw water as easily. the linseed oil

also binds the char together so it doesn’t come off as easily.

this was an important thing for us, since we didn’t want all that

visited to go home with black sot on their clothing.

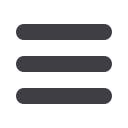

ex.1: overlaPPIng every second shIngle and every

second Batton(from 1:10 model In the Wood Work-

shoP)

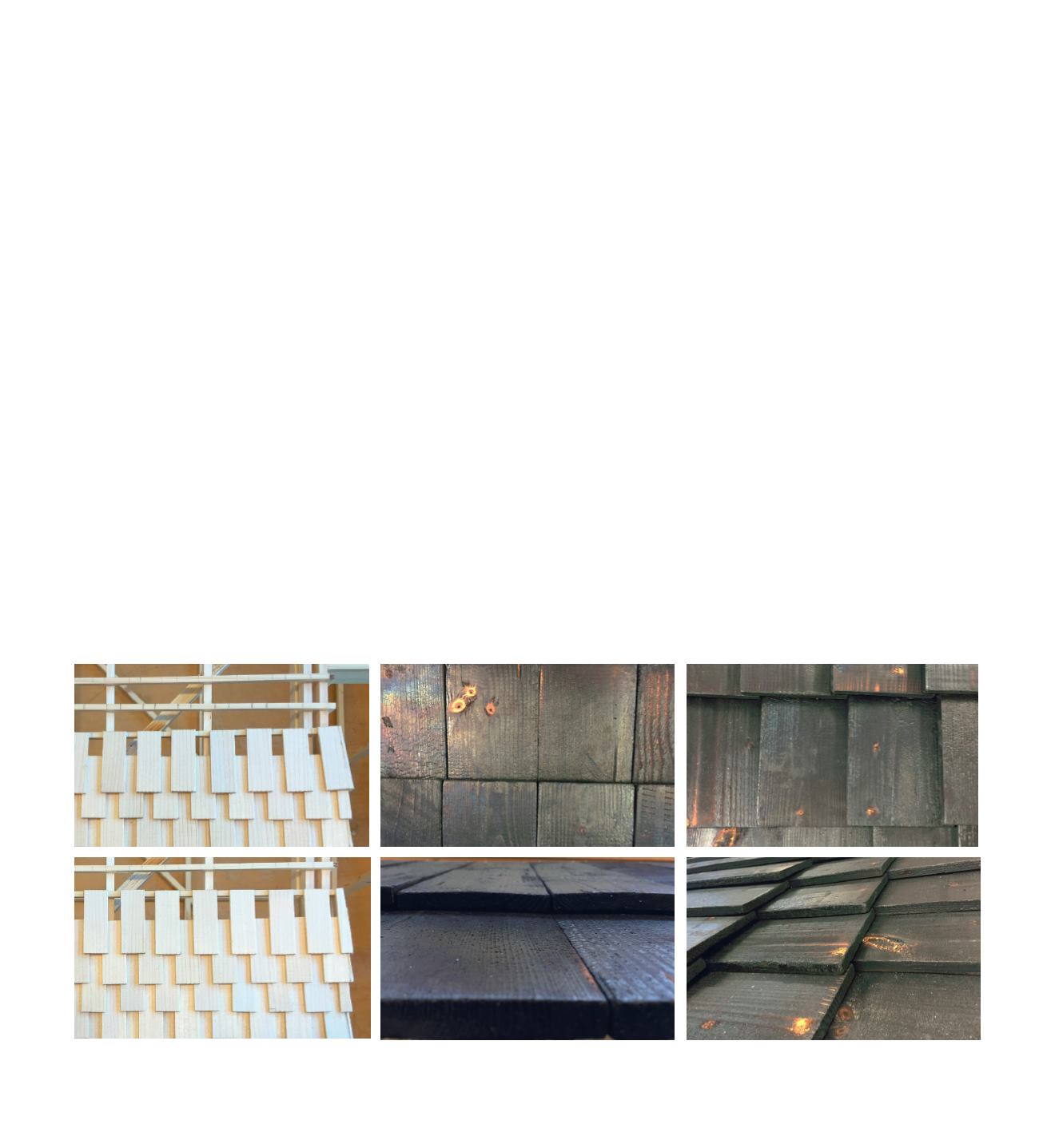

ex.2:edge to edge overlaPPIng every Batton

(sIte: havdal)

ex.3: oBlIque overlaPPIng (norWegIan: sulagt)

(sIte: havdal)