Table 5 :

Surface molar concentration of catalyst

Surface Catalyst concentration

Cu transfer

Exp Temp Cocatalyst Si Fraction

Cu

Sn

Zn

Cu

(°C) added

(day)

(mmol/m²) (µmol/m²) (µmol/m²)

(%)

Initial

/

-100µm (d1)

28,3

78

2607

1

25°C

/

+100µm (d2)

9,0

44

533

3

2

200°C

/

+100µm (d2)

15,0

198

747

6

3

300°C

/

+100µm (d2)

11,1

200

579

4

4

25°C

Sn+Zn +100µm (d2)

12,5

171

1223

7

5

200°C Sn+Zn +100µm (d2)

16,8

236

1269

5

6

300°C Sn+Zn +100µm (d2)

11,5

183

1464

5

7

25°C

Zn +100µm (d2)

12,9

116

2142

5

8

25°C

Al +100µm (d2)

7,1

66

564

3

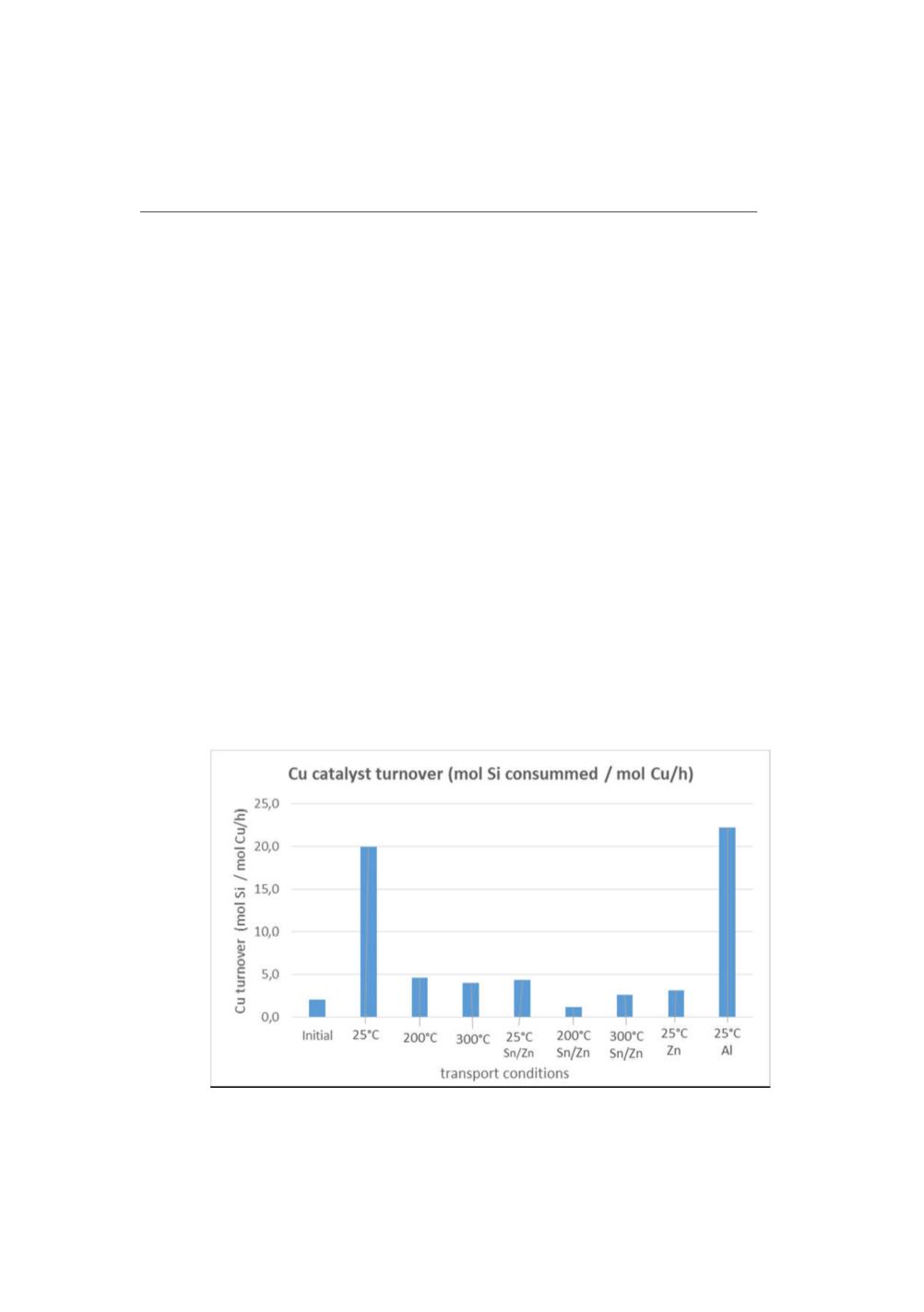

Reactivity of copper transferred to fresh silicon was strongly affected by transfer

conditions and was systematically higher than the reactivity of the initial contact mass

(day 1). Reactivity of transferred catalyst could be up to 10 times higher than initial

reactivity.

The graph below represent the catalyst turnover (mol Si converted /(mol Cu.h) ) for

some of the experiments.

Figure 6:

Copper catalyst turnover for different transfer conditions

136