46

PROCESS

planning

DESIGN TO PRODUCTION

During the design process we kept constantly

working on a 3D model in Rhino. Thanks to one

common master file with a defined grid and origin

point, it was easy to adjust and redraw several parts

of the design at the same time by different student

expert groups.

Meanwhile one team started to develop a

Grasshopper script that translates the 3D design

into useful numbers for cutting lists needed in the

building period. The flexibility in the code gives the

possibility to change the design even in a late phase.

Because it is linked to the geometry, the script out-

come adjusts while the 3D model gets changed.

Therefore, the 3D model needs to be as accurate as

possible. Small incorrect details can affect the

outcome immensely and lead to mistakes in the

building process. So, using this technology should

be considered from the very beginning of the

design.

Although we had produced cutting lists for all the

timber work of the project, we ended up just using it

for several parts such as battens, light constructions,

crossbeams and a few special massive wood

elements that could not be cut after the assembly.

Furthermore, the lists were helpful concerning

material calculations.

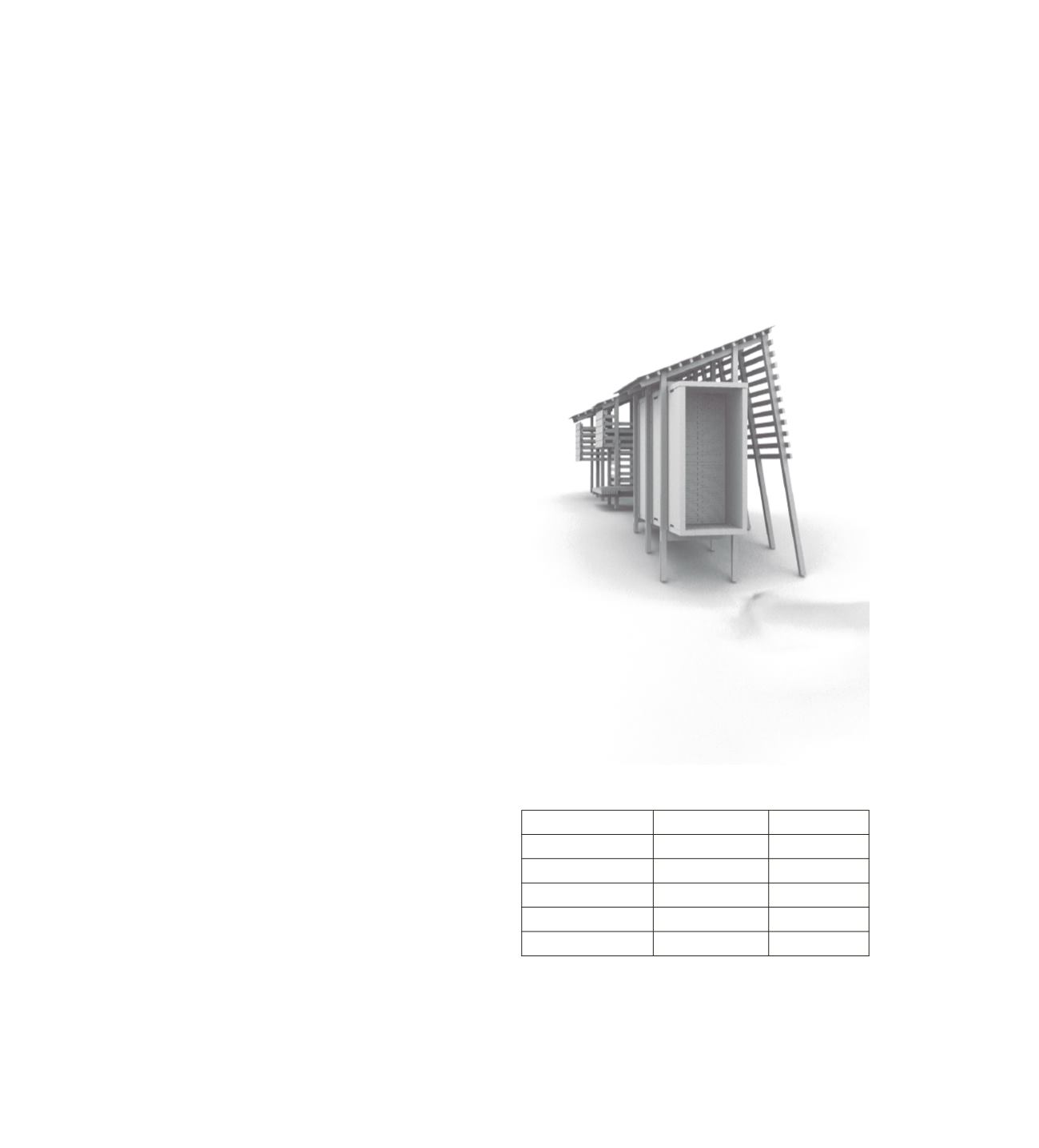

CROSSBEAMS

POSITION LENGTH

0A - 0B

1482

2B - 2C

1334

3B - 5B

1329

4A - 4C

2733

6A - 7A

1638

▵ Example of a cut list. The frames were given names according to posistion

and to make it easier to place other parts.

▵ Rendering of the final model.