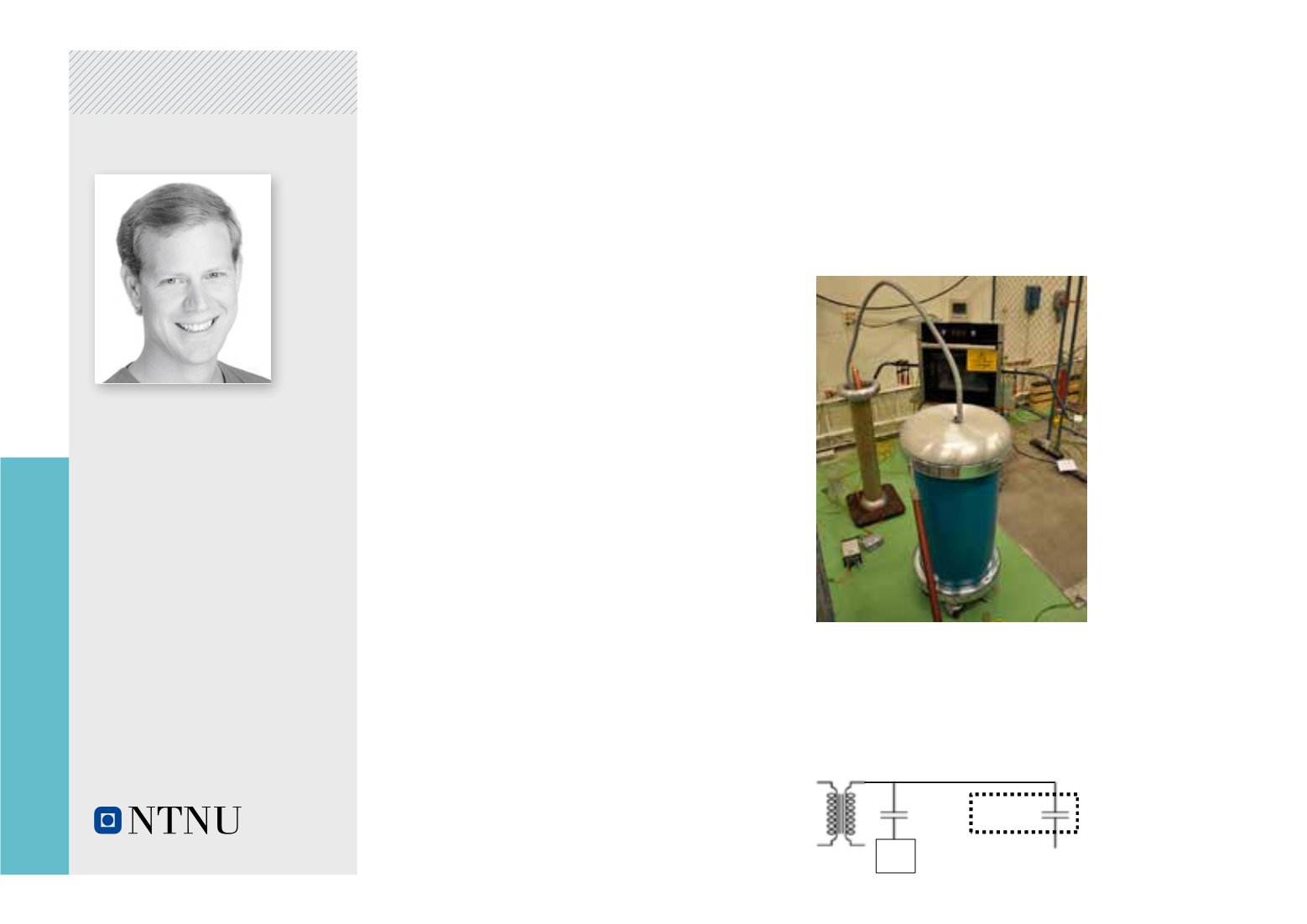

Laboratory test setup for partial discharge (PD) testing

at 50 Hz. Transformer in front, connected to a coupling

capacitor and the generator winding in back. An oven is

surrounding the winding and enables measurements at

different temperatures

PHD THESIS

Background

The majority of the Norwegian hydropower

generators was installed between 1960 and

1990, and many of these will soon reach the

expected lifetime and need refurbishment. One

main root cause for failure in hydro generators is

generally located to the groundwall insulation. It

is therefore important to have reliable diagnostic

methods to assess the groundwall insulation.

This reduces the risk of unexpected breakdown

and also too early winding replacement.

The objective of this PhD work is to correlate

insulation defects and non-destructive

measured quantities.

The method to be used is to first measure on

single generator windings with different history,

both spare windings and in-service aged windings

from both high and low voltage locations. This will

create a connection between the pristine system

and the aged system to quantify measurable

differences. Then, the faults will be localized by

acoustic or high frequency techniques before a

smaller area containing the fault, as well as a

non-fault area, will be measured again by the

same techniques. Next step is to reproduce the

faults artificially in a model system and prove that the

correlationsfoundintherealsystemisoriginatingfrom

theproposeddefects.

Relevant measurement techniques for condition

assessment are dielectric spectroscopy,

partial discharges, acoustic measurement and

dissection. These methods will characterize the

condition of the hydropower generator winding.

Department of electric

power engineering

2016-2019

Condition Assessment

of Generator Insulation

Supervisor:

Erling Ildstad

Co-supervisor:

Sverre Hvidsten,

Arne Nysveen

Torstein Grav Aakre

C

c

PD

Winding

Z

Oven

82