PHD THESIS

Background

Traditionally speaking, the runners of hydraulic

turbines have always been designed to operate

at synchronous speed. This is governed by the

fact that the generator has a certain number

of poles and it has to rotate at a certain

synchronous speed in order to produce the

required grid frequency. This is crucial for

uninterrupted electricity production.

On the other hand, synchronous speed turbines

have certain challenges when they are operated

at off-design load. Nowadays, turbines are

indeed required to operate at either part-load

or full-load much more frequently than before.

Despite the decreased efficiency at these

operating points, there is a higher dynamical

load present on the runner as well, which can

lead to severematerial cracks, expensive repairs

and decreased power plant reliability in general.

Therefore, it’s considered that variable speed

operation can improve efficiency and stability of

the turbine.

The idea of using variable speed generators is

relatively old but opens future prospects only

because the price of such generators are getting

lower nowadays. But, as reported in previous

research, not all turbine runners can gain

benefit from operating at variable speeds.

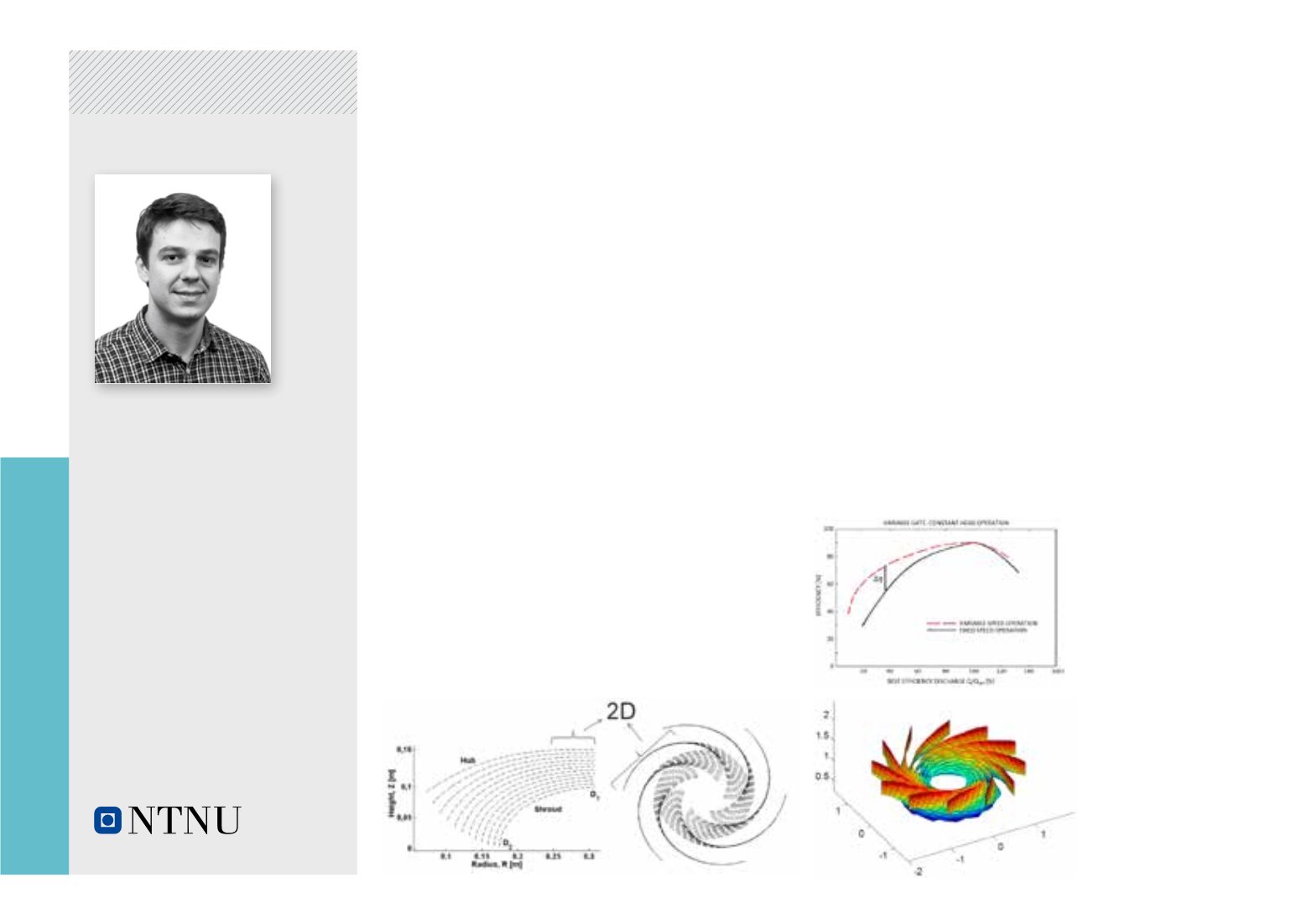

Both the idea and objective of this research is to

develop new tools and methodology for design-

ing a turbine that will operate at variable speeds

almost exclusively. A better understanding of

the design philosophy is then required in order

to sustain the parametric study needed. Finally,

a model runner will be produced and tested in

order to compare the performance against the

existing Francis-99 runner.

Department of Energy and

Process Engineering

2016-2019

Design of a High-

Head Francis Turbine

for Variable Speed

Configurations

Supervisor:

Ole Gunnar Dahlhaug

Co-supervisor:

Chirag Trivedi

Igor Iliev

62