Background

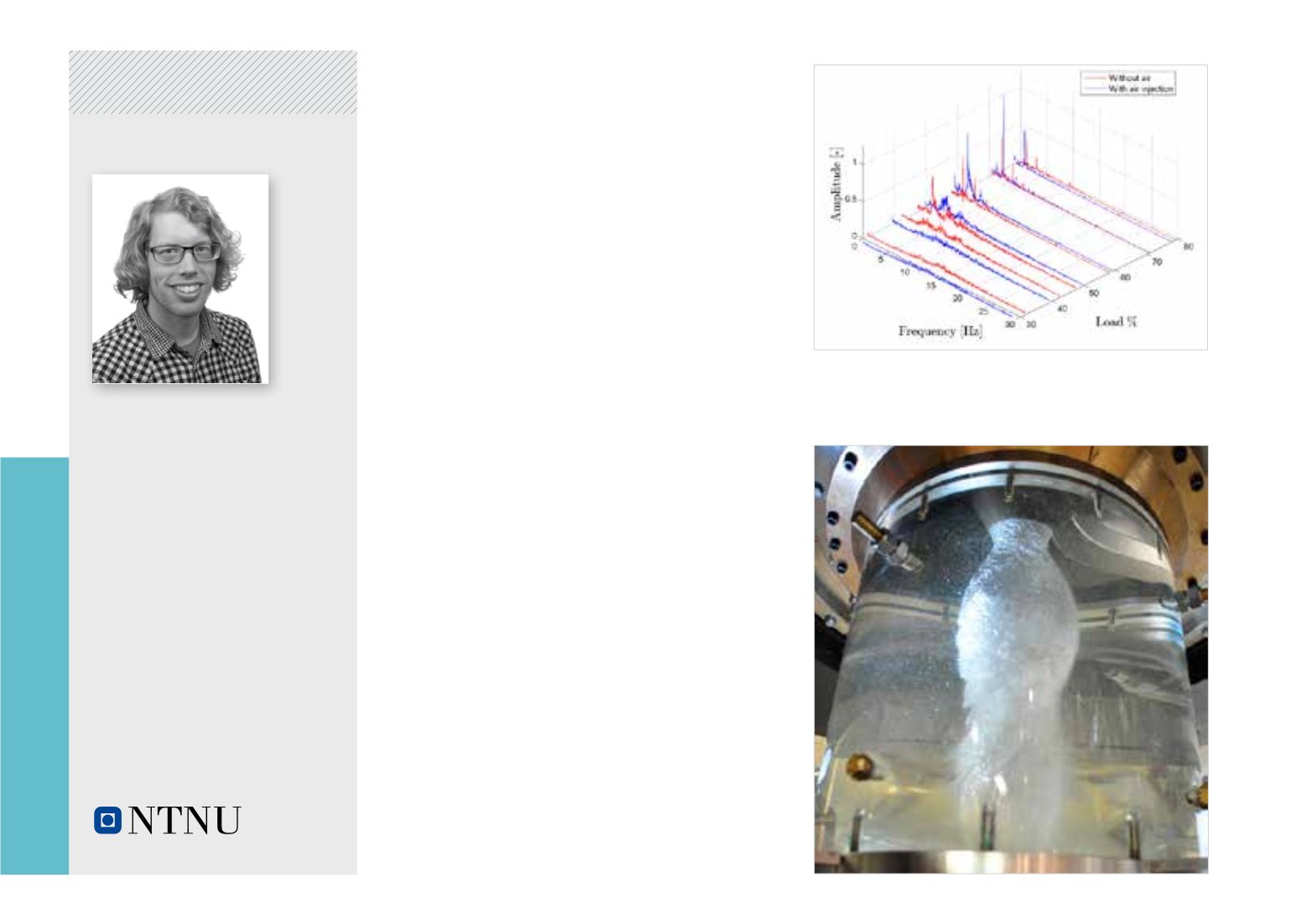

Increased demand for flexibility in the power

supply has lead to an increase in operation

outside the best efficiency point. Part load

operation causes a dramatical changes in

the flow regime of the draft tube. For Francis

turbines operating at part load, there is a

mismatch between swirl generated by the

guide vanes and the momentum extracted

by the turbine runner. The vortex breakdown

that occurs in the draft tube is recognized as

the main cause of severe flow instabilities and

pressure fluctuations. The consequences are

known to be heavy vibrations and noise, which

may cause high fatigue load and ultimately lead

to mechanical failure. Mitigation of pressure

pulsations is considered an important task since

it will increase the life time of the turbine.

Different methods for mitigating the vortex

rope and the pressure fluctuations, such as

air injection, water injection, and runner shaft

extension have been investigated. The aim

of this thesis is to further investigate these

methods to find the best way of mitigating

pressure pulsations.

PHD THESIS

Department of Energy and

Process Engineering

2013-2017

Pressure Pulsations in

Francis Turbines

Supervisor:

Ole Gunnar Dahlhaug

Co-supervisor:

Torbjørn K. Nielsen

Peter Joachim Gogstad

Frequency analysis of a pressure pulsations in a Francis

draft tube

58