55

Department of Energy and

Process Engineering

Spring 2017

Air Injection in Francis

Turbines

Supervisor:

Michel J. Cervantes

Livia I. Pitorac

Background

The introduction of renewable energy such as

wind and solar involves a significant increase

of the load variations as well as start/stop

cycles for hydraulic turbines to regulate the

grid frequency. As a turbine away from the best

efficiency point, vortex breakdown may occur

in the draft tube, a diffuser found immediately

after the runner. Vortex breakdown leads to the

formation of a rotating vortex rope (RVR) when

a turbine is operated below the best efficiency

point for single regulated turbines.

A RVR creates large axial and radial pressure

pulsations and thus limits the operating range

of the turbine and leads to wear. Mitigation of the

RVR has been researched for many years. Air

injection is among the most popular methods

to decrease the pressure oscillations. Water

injection and fins have also been investigated.

However, none of these methods have been

distinctly successful.

MASTER THESIS

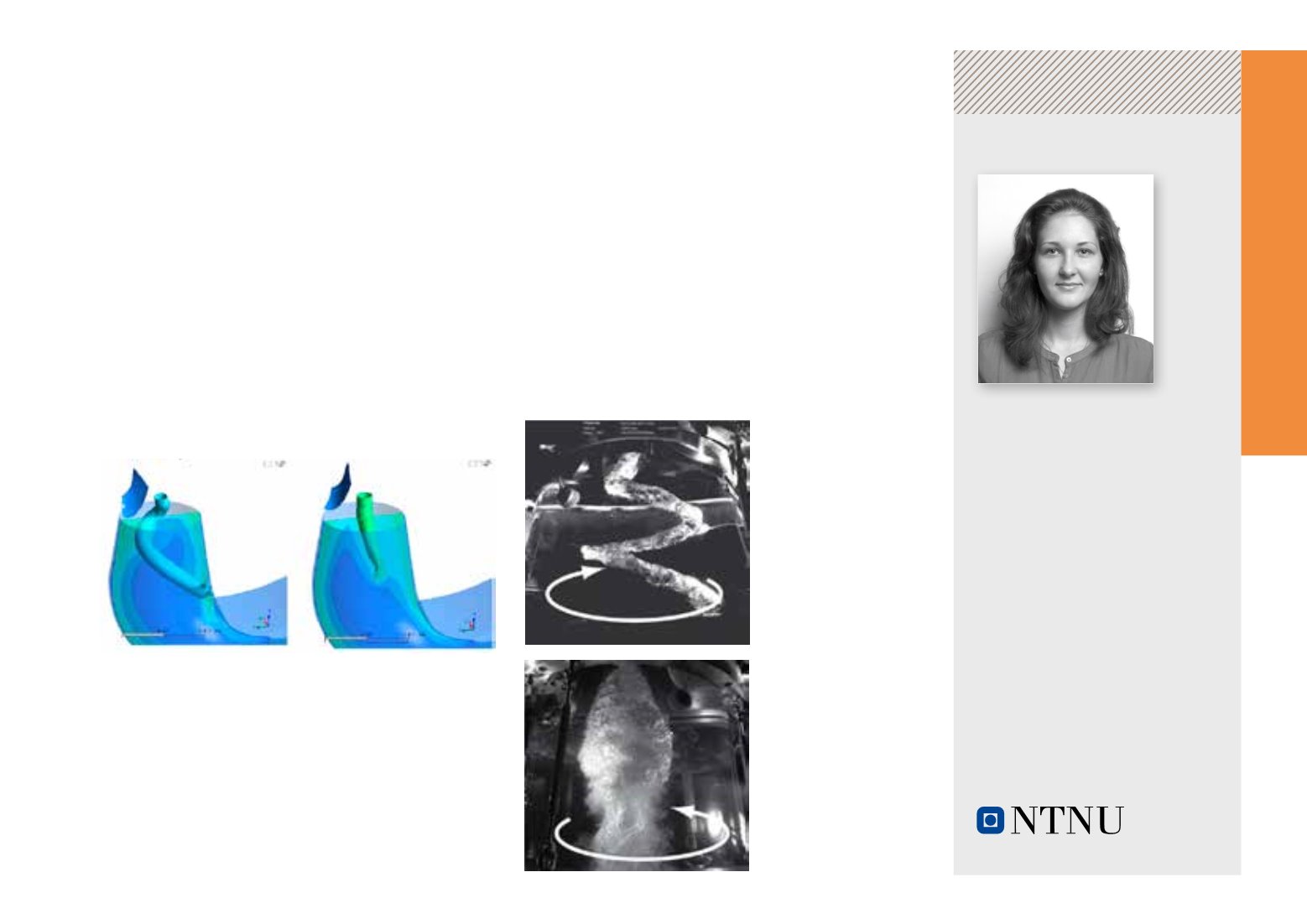

This picture shows the 3D iso pressure surface during

part load, without (left) and with (right) jet injection (Resiga

2006,23rd IAHR Symp., 192)

RVR formation during

part load operation

RVR formation during

full load operation