Department of Chemical Engineering

Annual Report 2015

15

nanoparticles modified with certain chemical groups for

extraction of the naphthenic acids before formation of

the metal naphthenates (mitigation strategy) as well as

removal of the metal naphthenates (remediation

strategy). The nanoparticles will be designed according

to their affinity to the carrying phase (oil, water, or

interface). The methodology will bring concepts with the

following advantages:

Nanoparticles will be recovered at the end of extraction,

regenerated and recycled.

No toxic chemicals will be lost into oil or produced water

due to material recovery at the end of the process.

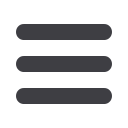

Figure: The synthesized Fe3O4 MNP before (A) and after

applying a magnet beneath the flask (B).

NEXT-GENERATION WAX INHIBITORS FOR THE

OIL AND GAS INDUSTRY (VISTA FUNDING 2015-

2017)

Heavy crude oils often contain waxes that can form large,

volume spanning networks upon crystallization,

effectively forming a strong gel that inhibits flow in

pipelines even at relatively low wax contents. This is

avoided during normal flow by the continuous

breakdown of this gel network under flow, but during

operational stops this gel network can result in a serious

restart problem.

The object of this project is developing new mechanism

for wax inhibition in heavy oils by morphological

modification of silica nanoparticles, trying to avoid major

reliance on chemical modification and toxic chemicals.

The major benefits of this new technology include low

dosage rates, environmental friendliness by keeping the

nanoparticles in the oil phase, and potential reuse of the

nanoparticles. The nanoparticles should work by

optimizing entropic repulsion and modifying wax

crystallization.

The project uses rheology, differential scanning

calorimetry and quartz crystal microbalance to evaluate

nano-particle formulation effect and effectiveness on

waxy oil gels, and aims to further evaluate the

environmental impact of using such nano-particles on

produce water, emulsions and sustainability of the

formulations.

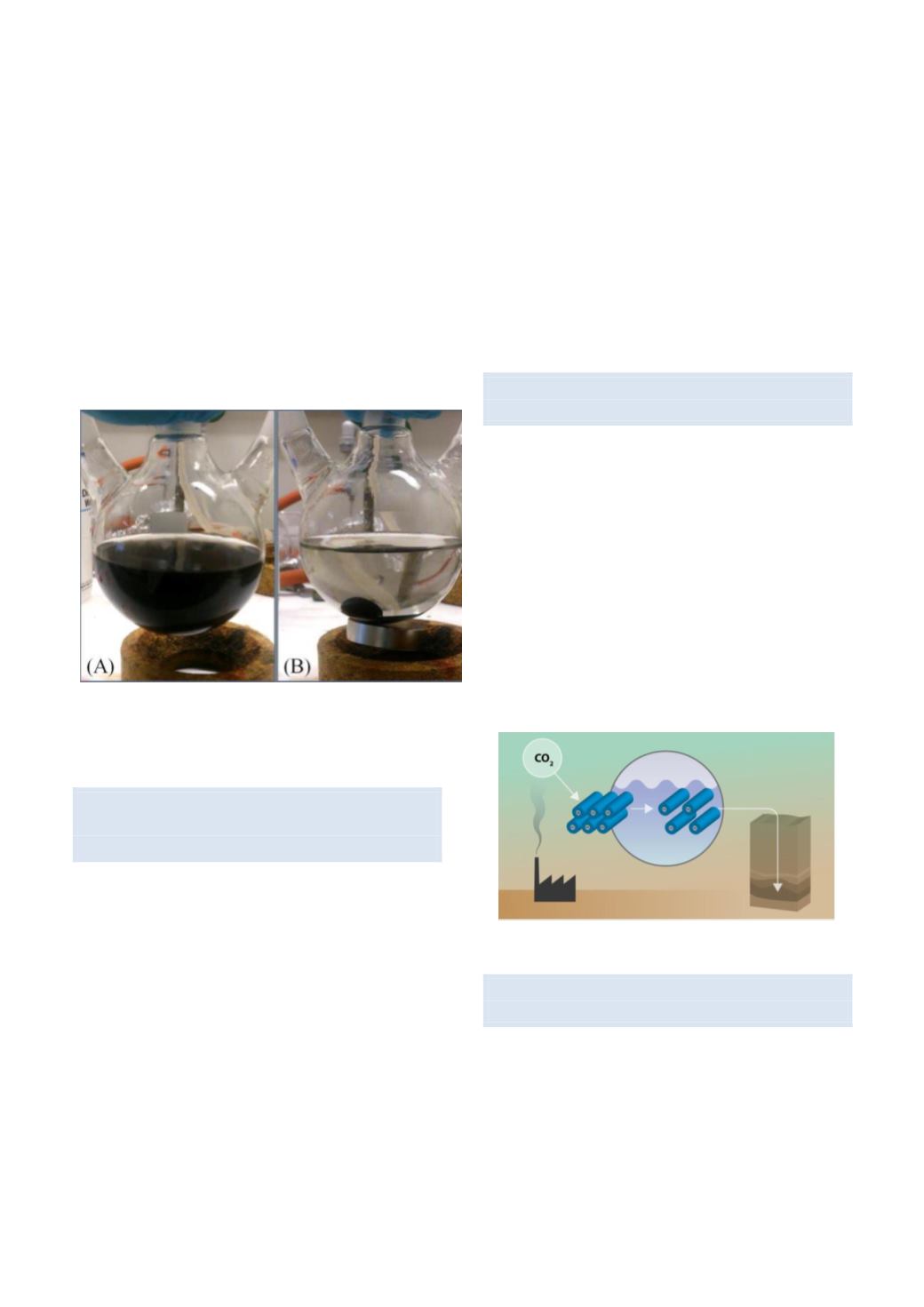

CO

2

CAPTURE IN CONFINED SURFACTANT

GEOMETRIES (NFR AND GASSNOVA)

A new collaborative project to use liquid crystals for CO2

capture, transport and storage is being performed

between Ugelstad Laboratory and University in Bergen.

The project is financed by CLIMIT, which is a

collaboration managed jointly between the Research

Council of Norway and Gassnova. The idea is to use liquid

crystal geometries to provide tailored internal

environments to capture CO2, and retain the CO2 inside

the liquid crystals for facilitated transport and also

storage in geologic acquirers. The liquid crystals provide

a primary thermodynamic sealant mechanism for CO2,

assuring continued storage in the case of caprock

fracture.

Figure : CO2 capture, transport and storage using liquid

crystal technology (Illustrasjon Eivin Vetle).

NORCEL: THE NORWEGIAN NANOCELLULOSE

TECHNOLOGY PLATFORM (NFR 2013-2018)

The vision of the NORCEL project is to develop an

internationally leading research platform for production,

modification and control of morphology, chemistry and

three-dimensional structures of nanocellulose at a

fundamental level. One of the applications in focus in this

project is enhanced oil recovery (EOR), and rheology of

nanocellulose dispersions is a key factor in this respect.

The project is led by PFI and has both national and

international partners. The project is funded by the