Department of Chemical Engineering

Annual Report 2015

12

RESEARCH PROGRAM

NEW STRATEGY FOR SEPARATION OF COMPLEX

WATER-IN-CRUDE OIL EMULSIONS: FROM BENCH

TO LARGE SCALE SEPARATION, PETROMAKS 2

(2016-2019)

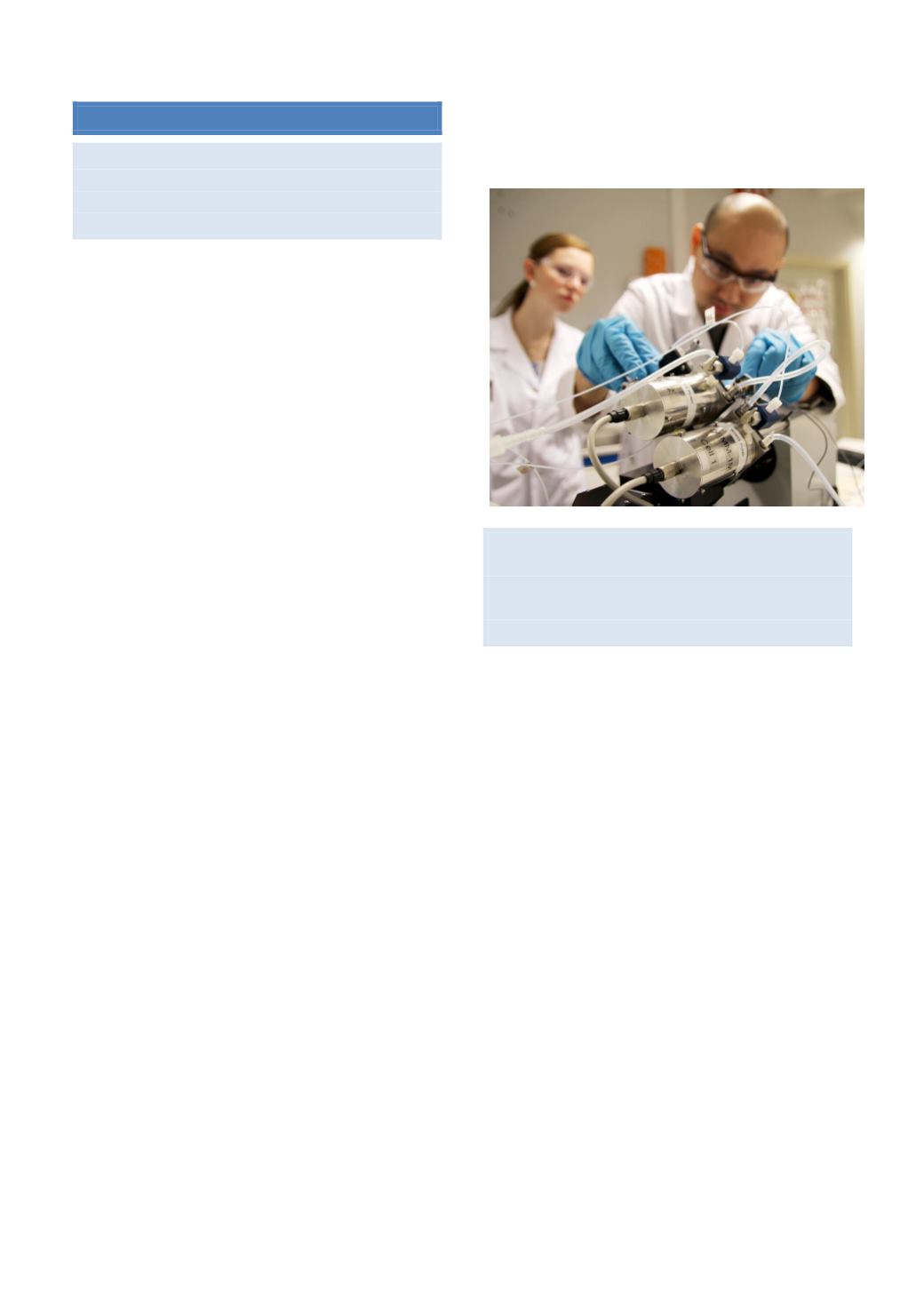

Water

‐

in

‐

crude oil emulsions (w/o) are ubiquitous in the

petroleum production industry and they need to be

processed to obtain anhydrous oil and pure water. As

environmental regulations become more rigorous

(OSPAR), it is of outmost importance to improve oil-

water separation technology in order to successfully

process increasingly complex production fluids. That is

why this new project aims to improve the knowledge of

water-oil separation processes and to develop new

separation strategies by focusing on two aspects:

Better understand the systems problematic in oil-water

separation namely the formation of complex multi-

component interfaces around droplets and the dense-

packed layers with high water content (DPL). The

complex interfacial layers will be characterized by state-

of-the-art techniques like ellipsometry, Quartz Crystal

Microbalance (QCM), interfacial rheology in shear and

dilation, NMR, Film drainage experiments, Isothermal

Titration Technology (ITC), FT-ICR-MS and neutron

reflectometry. In addition to this experimental work,

dissipative particle dynamics (DPD) modelling will be

carried out to better understand structure of these

systems.

Combines electrocoalescence and chemicals to improve

oil-water separation by performing experiments at

various scales followed up by modelling. The new

destabilizing agent classes will be developed in

collaboration with chemical vendors (AkzoNobel and

NalcoChampion). These demulsifiers will be combined

with electrocoalescers and tested in large scales at

Wärtsilä Oil and Gas facilities.

The project will have Ugelstad Laboratory as host

institution with Prof. Johan Sjöblom as project manager

and will be conducted in collaboration with University of

Alberta, Canada (Prof. Zhenghe Xu), Swiss Federal

Institute of Technology (ETH) in Zurich, Switzerland (Prof.

Jan Vermant), and IFE (Prof. Roar Skartlien and Kenneth

Knudsen) with a strong implication from industrial

sponsors especially Wärtsilä Oil and Gas (Drs. Morad

Amarzguioui and Erik Bjørklund). The project is funded

by the Norwegian Research Council via a Petromask II

grant and by the following industrial sponsors:

AkzoNobel, NalcoCampion and Wärtsilä Oil and Gas. This

project will educate 3 PhD candidates and 1 post-doctor

as well as well as several master students.

INFLUENCE

OF

PRODUCT ION

AND

EOR

CHEMICALS ON PRODUCED WATER QUALITY -

FUNDAMENTAL KNOWLEDGE OF THE FLUIDS FOR

IMPROVED PRODUCED WATER MANAGEMENT,

PETROMAKS 2 (2016-2020)

The overall goal of the project is to investigate how

production and enhanced oil recovery (EOR) chemicals

influence produced water quality and treatment.

Production chemicals giving rise to poor produced water

quality is already an issue within the petroleum industry,

while the effects of EOR chemicals on the water quality

will increasingly become a challenge as chemical flooding

methods are likely to emerge in the years to come. There

is, however, a lack of systematic investigations focusing

on how the use of the various chemicals affects the

produced water quality. Fundamental studies of

synergies between indigenous and added components in

produced water, the resulting interfacial phenomena

and ultimately the implications for produced water

treatment are areas of research which will be addressed

in this project. The studies will range from small-scale

interfacial studies to pilot-scale testing of produced

water treatment units, aiming at revealing underlying

mechanisms affecting produced water quality and

produced water treatment efficiency.

2 PhD candidates 1 post.doc and several master students

will be educated within the project. The industrial

partners are Statoil, Total and Schlumberger. In addition,

the Research Council of Norway will finance the project.