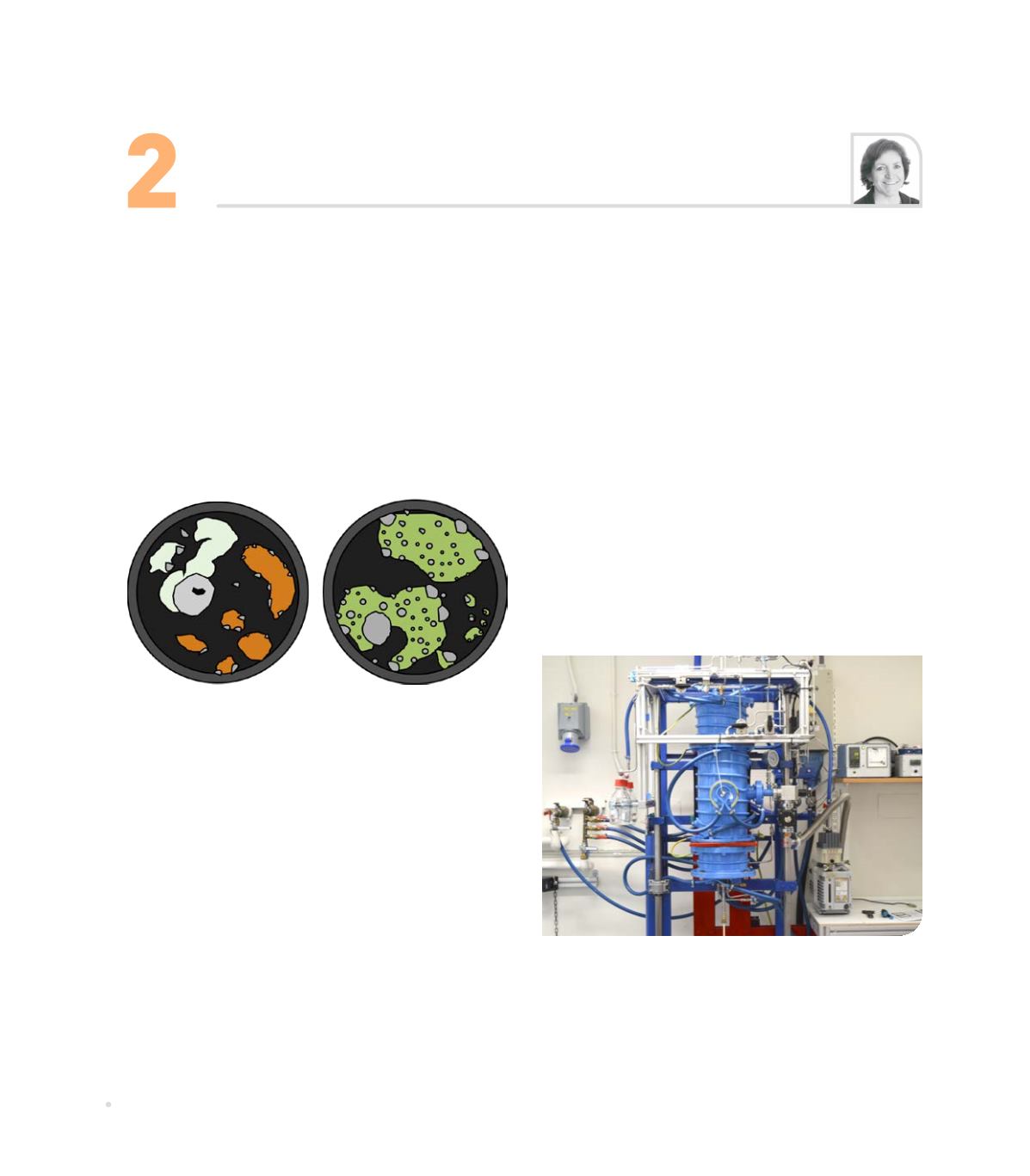

Without sulfur

Without 1 mass % sulfur

In 2016, the main focus continued to be on the reduction

mechanisms in Mn and Si production. In

SiMn reduction

the effect of foaming and sulphur content on the reduc-

tion mechanism was found. In the Si process, one Si fur-

nace was excavated and it was established how diverse

the FeSi and Si furnace-interior may be. Samples with

sulphur had metals inside the end-slag, as shown in

the Figure. PhD candidate Pyunghwa Kim got the award

for the best poster, “Behavior of Assmang and Comilog

Ore in the SiMn Process” at the 10th International

Conference on Molten 2016 Slags, Fluxes and Salts

Reduction in Seattle (USA).

In the small scale,

the formation of

α

-SiC

from

β

-SiC

was found to occur above 2200 °C. It was also shown

how Si was already produced at about 1700 °C in the

siliconcarbide structure. PhD candidate Sethulakshmy

tells more about her research at page 33.

In other areas it was shown that more than 50 % amor-

phous SiO

2

can be present when quartz transforms to

cristobalite, how Mn-briquettes deteriorates with time,

and how the phase structure in TiO

2

slags vary with cool-

ing rate.

In RD2, a total of six students and one associated stu-

dent finished their MSc theses. They have all continued

working for this industry, as four of them continued with

their PhD in the SFI or SFI related projects, and three

of them started to work for the industry partners. There

were two international exchange students in 2016; one

master student from Japan working with SiMn reduc-

tion, and one PhD student from Brazil working with

charcoal in the Si production. In 2016, a number of PhD

students started their projects. In addition to one PhD

student funded by the SFI, two new PhD students were

funded by NTNU and two funded by SINTEF and Elkem

as industrial PhD’s. In addition to internal reports, four

publications were presented at two conferences.

Primary Metal Production (RD2)

by Professor Merete Tangstad

16

Highlights of 2016 from the Research Domains