7

goals and ReseaRch Plan

nm

Atomic

scale

Microstructure

Material

Component

Joint

Structure

System

µm mm cm m

Physical scale

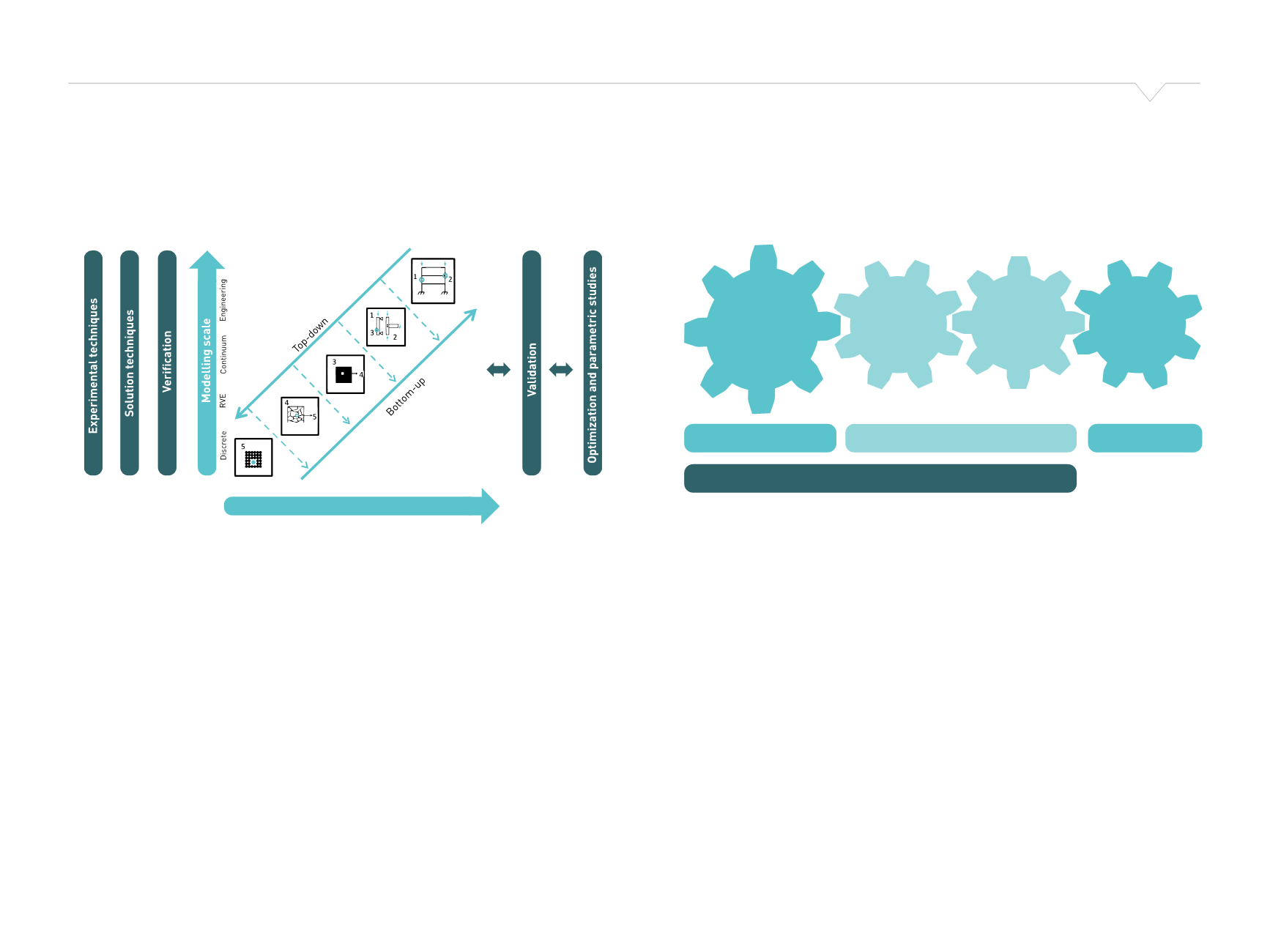

Figure 1: Research methodology.

Figure 2: Structure of research, technology transfer and industrial implementation.

Multi-scale

testing,

modelling and

simulation

Methods

and

Tools

Industrial

Implementation

Ready-to-use

technology

Innovation

Basic research

SFI-CASA

Technology transfer

Industry

Research methodology and industrial implementation

The activities in CASA will represent a step change for advanced

structural analysis for industry and public enterprises as it is

based on multidisciplinary and interdisciplinary research

on different physical scales. The research methodology

adopted to meet the overall objective is presented in Figure

1. As illustrated, a structure or product can be studied on

different physical scales just like the modelling scales

(there is also a time scale which reflects the duration of

the physical events to be studied, but this is not shown in

the figure). By using a top-down/bottom-up approach the

main goal of the research will always be the final structure

or product. In some cases, microstructural modelling or even

modelling on atomic scale may be required to understand the

underlying physical mechanisms of the observed material

response to loading. However, for joints or components

the behaviour may be sufficiently well understood on the

continuum scale. In all cases, research at the Centre will be

designed to obtain modelling frameworks on the material and

structural levels that are suitable for industrial applications.

Many research topics and activities are addressed on the

various scales: testing and modelling of materials and

structures, numerical solution techniques, experimental

techniques, verification and validation approaches, and

optimization methods and parametric studies. Verification

is the process of determining that a computational model

accurately represents the underlying mathematical model

and solution, whereas validation deals with the relationship

between the computational model and the physical reality.

Figure 2 illustrates the important interlink between Basic

research, Technology transfer and Industry. The Methods

and Tools Programme is a synthesis of Basic research,

where guidelines and recommended practice for credible

numerical structural analysis is established. The Industrial

implementation programme is the link between the Methods

and Tools Programme and the industrial use of the research

and technology developed at the Centre for innovation.