Basic HTML Version

25

SAMC

o

T • Annual report 2012

Fig. 17. Damage to the steel structure caused by the ice: a)

at full-scale (S. Hänninen), b) in laboratory.

The tests were conducted in the ice basin at Aalto Uni

versity, Finland, where ice masses were towed into a

moored structure with a deformable panel mounted in

the impact zone.

Both the ice and the structure experienced notable de

formations during impact. The characteristics of the ice

impact zone and panel deformations compared fairly well

with the data from full-scale observations (see Fig. 17).

We believe these experiments are the first to focus

exclusively on the coupled damage behaviour of both

ice and steel, with our findings demonstrating realis

tic damage to the steel plates. However, more damage

to the steel structures, including stiffening systems,

would further enhance the knowledge of this complex

coupled deformation process. Based on the knowledge

learned during the Aalto experiments, new experiments

are planned in 2013/2014 with a focus on obtaining more

data on ice-steel interactions producing larger defor

mations than achieved in the Aalto experiments.

Friction of Sea Ice on Sea Ice

Knowledge of ice friction plays an important role in

a number of Arctic engineering applications. For in

stance, it affects the designs of icebreakers and their

performance in ice and it is necessary for the calcula

tion of ice loads on sloping offshore structure construc

tions.

Additionally, friction is a fundamental process during

the brittle compressive deformation of cold ice. Friction

is the largest sink of energy during the rafting and ridg

ing processes of sea ice. Therefore, the results of the

numerical simulations describing these processes are

significantly affected by the choice of the input for the

friction coefficient.

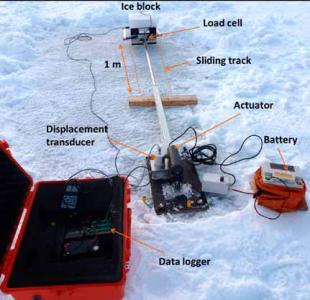

“During my field study with first-year ice (Barents Sea

and fjords at Spitsbergen) and second-year ice (Northeast

Greenland), I did tests where ice blocks were slid along

tracks using a pulling mechanism, a linear actuator,” says

Sergiy Sukhorukov, a SAMCoT doctoral student.

b)

a)

Fig. 18. Experiment set-up for friction tests.