Basic HTML Version

48

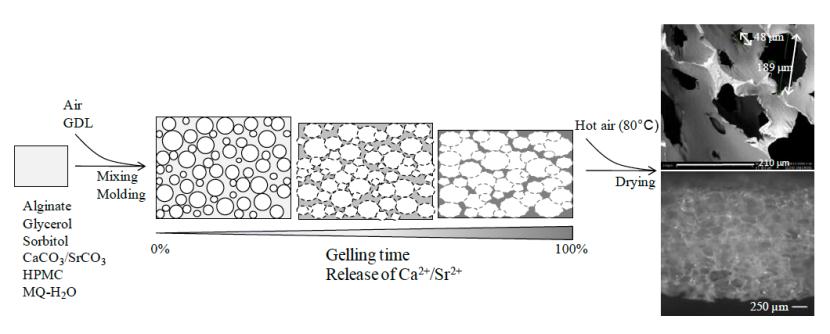

1.2.21. Alginate

foams: 3D

cell

cultures

A foamy material is often advantageous for growing mammalian cells in a

controlled manner. Cells can be added to the foam, whereby they distribute

evenly in the porous structure in 3 dimensions (3D). Foams seeded with

appropriate cell types (stem cells or differentiated cells) are promising

alternatives in tissue engineering.

Alginate foams may be obtained by freeze-drying alginate solutions, but

recently

14

a new method to prepare foams with better control over porosity

and mechanical properties was developed. In this case the CaCO

3

/GDL

gelation method is applied in a slightly modified way:

First, a suspension of Na-alginate containing CaCO

3

microparticles and GDL

in addition to plasticizers (glycerol, sorbitol) and HPMC

15

(foaming agent) is

prepared. The low rate of gelation allows the system to mix with air to form

stable bubbles.

As the alginate solution slowly forms a gel, the porous structure becomes

permanent as air bubbles are prevented from rising or coalescing. The porous

gel is the dried and stored (if necessary, sterilized) before use.

Figure 28. Preparation of alginate foams (Courtesy Therese Andersen, Ph.D.

thesis NTNU, 2013).

Cells are seeded into the foams simply by adding the cell suspension (in

appropriate buffer). The cell suspension fills the pores, and the cells thus

distribute evenly throughout the foam.

In order to ensure efficient seeding it is advantageous to use some Na-

alginate in the cell suspension. The added alginate will react with Ca

++

ions

(or alternatively Sr

++

) already present in the dry foam and form a gel inside the

pores. The final product is a homogeneous alginate gel (no longer a foam).

14 PhD thesis Therese Andersen, NTNU, 2013

15 HPMC: Hydroxypropyl cellulose