Basic HTML Version

20

Alginates are used in the food industry (as thickeners and stabilizers), and in

the pharmaceutical industry (tablet formulations, drug delivery, biomaterials

for tissue engineering etc.) mainly due to their viscosifying and gelling (with

Ca

++

) properties, but are also used in textile printing pastes, surface treatment

of paper and cardboard, in welding electrodes.

Most industrial applications of alginates are based on the ability of alginate

solutions (2-10%) to form gels when calcium salts are added.

1.2.3. Structure of alginates

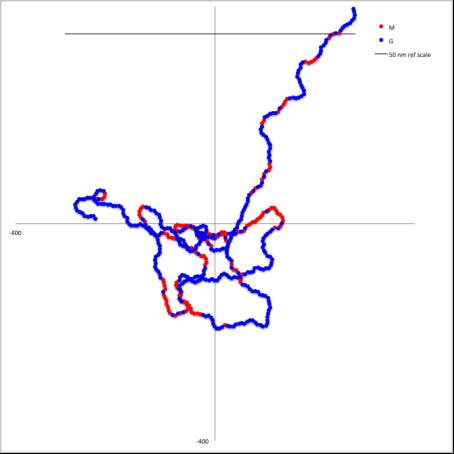

Alginates are sometimes described as binary

co-

polymers because they

contain two different monomers (abbreviated M and G), arranged in a variety

of sequences. They are further linear, meaning they are not branched.

Until the biosynthesis of alginates was fully understood (quite recently),

statistical considerations adapted from the science of synthetic copolymers

were used. It was believed alginate chains were co-polymerized from mixtures

of M and G precursors. We now know that alginates are produced

(enzymatically, of course) in a completely different (and even more

interesting) way. Fortunately, this simplifies the understanding of alginate

structures. Another consequence is that the term ‘co-polymer’ is no longer

appropriate

6

.

The first step in the biosynthesis of alginate is to make a homopolymer:

mannuronan (poly-mannuronic acid) from the precursor GDP-D-mannuronic

acid:

6

Copolymers normally refer to polymers made up in a polymerisation process starting from a

mixture of two monomers: nA + mB

→

A

n

B

m

. As we will see, alginates are certainly not made

in this way.