Basic HTML Version

14

MASTER OF SCIENCE IN LIGHT METALS, SILICON AND FERROALLOY PRODUCTION

MASTER OF SCIENCE IN LIGHT METALS,

SILICON AND FERROALLOy PRODUCTION

NUMBER OF STUDENTS ADMITTED: 13

ADDRESS: NTNU, Faculty of Natural Sciences

and Technology.

NO-7491 Trondheim

PHONE: + 47 73 59 41 97

E-MAIL: studier-nt

@

nt.ntnu.no

URL: www.ntnu.edu/studies/mslisifer

www.ntnu.no/nt/english

STUDY ADVISOR: Brit Wenche Meland

ADMISSION REQUIREMENTS AND APPLICATION

DEADLINE: see page 1.

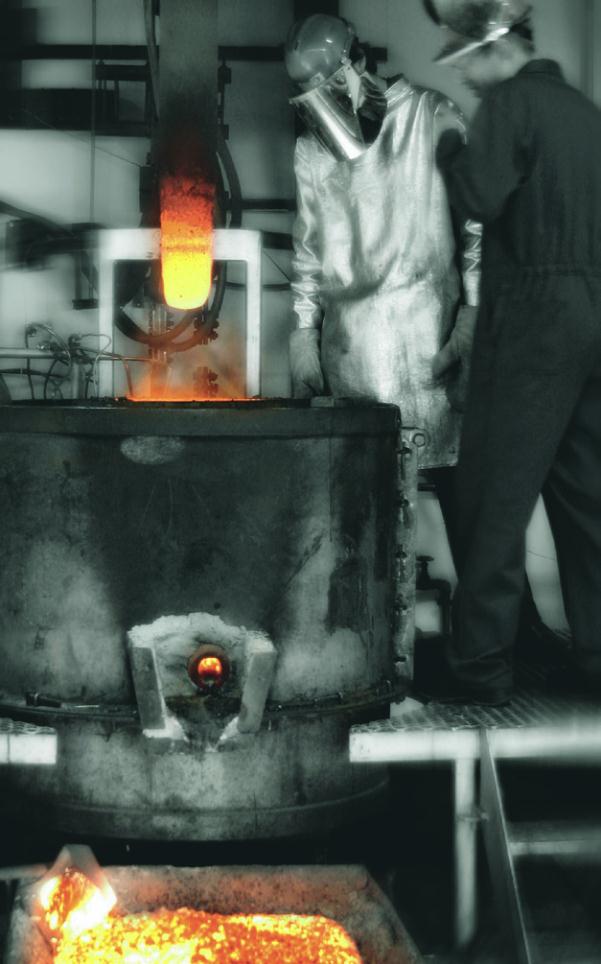

AbOUT THE PROGRAMME

Industrial production of light metals,

silicon and ferroalloys based on

Norwegian expertise and technology

couples a high level of societal aware-

ness to manufacturing of value-added

products.

This study programme can be described

as the study of processes and industrial

aspects of high temperature production

of metals from their stable oxides;

including recycling, environmental and

energy related issues.

Candidates who have completed their

study in the program: "Light Metals,

Silicon and Ferroalloy Production" shall

have:

w Thorough knowledge of the manu-

facturing and refining processes

that are important for industrial

production of silicon, ferro alloys,

light metals, including carbothermal

processes, electrolysis and refining

processes

w In-depth knowledge and un-

derstanding of what determines

chemical equilibrium, how this

can be described by Gibbs energy

functions and phase diagrams, and

its significance in the development

and operation of high temperature

industrial processes

w Knowledge of industrial applications

of transport phenomena like heat

and mass transfer for single phase

and multiphase systems

w Application skills for the combination

of thermodynamics, reaction kinetics

and transport phenomena with

careful attention to economics and

environmental issues to produce

metals from natural and manmade

recourses

All courses are given in English and are

directly related to electrochemistry,

pyrometallurgy and materials techno-

logy. The students will study and perform

industry related research projects

through close cooperation between

university and industry.

Photo: Melinda Gaal