Lasercutting with Siemens NX

Engineering software, Manulab

This post describes how to export cutting data from your Siemens NX 3D-model to be cut with a laser cutter. Some of the most common file format for laser cutters are DXF or SVG. Several methods for exporting DXF-files exists in NX. One convenient method is to use the NX-sheet metal application.

DXF export method (pictures further down):

- Create planar geometry in the NX-modelling application. For this example we are using a simple shelf with rectangular plates.

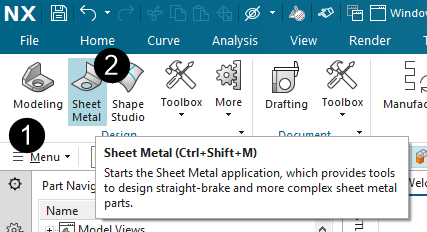

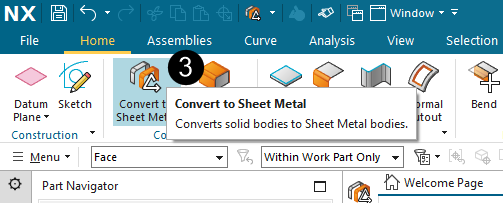

- Invoke the NX sheet metal application and select Convert to Sheet Metal.

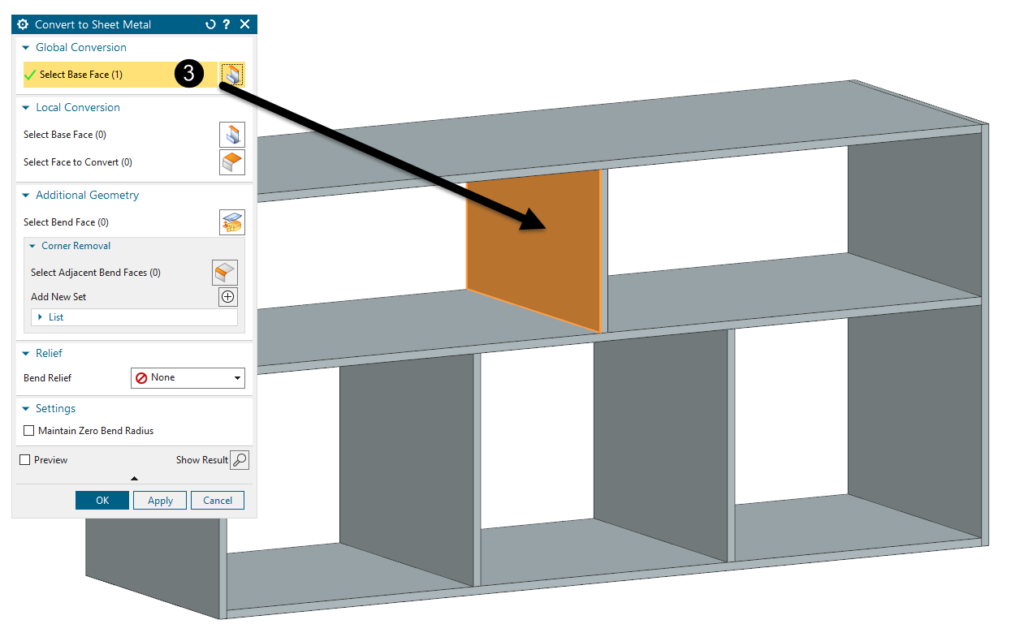

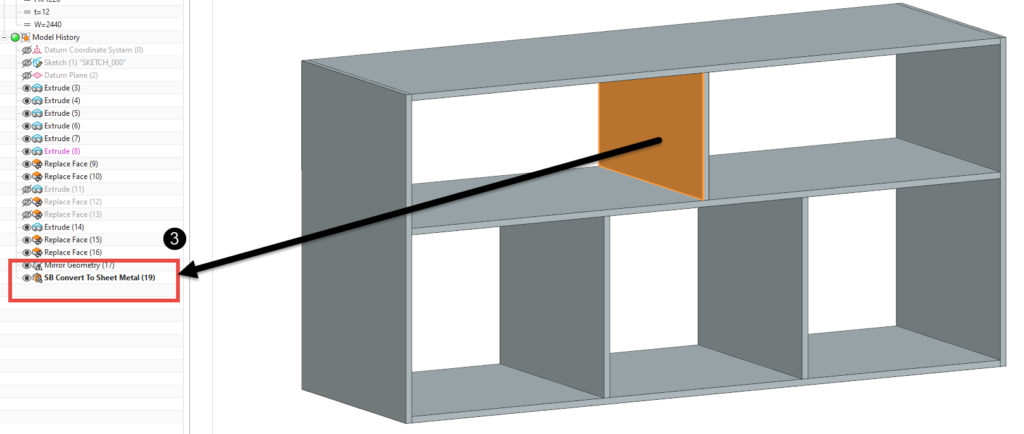

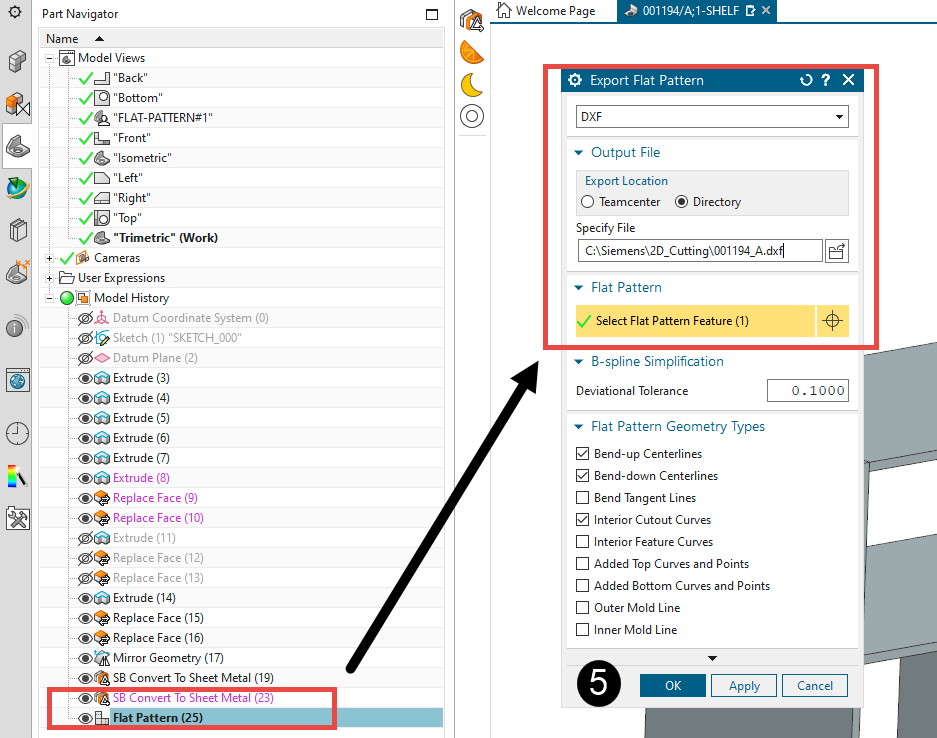

- Select Convert to Sheet Metal and select a Base Face on the part you want to cut and click ok. Not much really happens here, but a SB Convert to Sheet Metal feature shows up in you model history tree.

- The next step is to create a Flat Pattern feature. This feature extracts all face edges from your component and prepares them for export.

- Export flat pattern to dxf by using Export Flat Pattern. Select the flat pattern feature in the part navigator and set destination directory and filename. If you are preparing several parts/solids for cutting, you have to repeat step 3 to 5 for each part.

- When you have exported the dxf(s), you may delete the convert to sheet metal and flat pattern features or just keep them for later since they are associative and are updated when you change your part geometry.

- Bring your DXF-files to the lab and start cutting. Please follow guidelines and instructions from lab-staff.