Crack-detecting waves

Whether they transport oil, gas, water, or other substances – you do not want them to leak. But if a pipe is in an inaccessible area, how do you then check for cracks? And if there are any – are they critical, or not?

The heat is on – transducer design

To inspect and test oil pipelines is crucial – both for health and safety, and for the environment. But the harsh conditions mean specialised equipment is imperative. When using ultrasound to perform non-destructive testing, this translates into a need for transducers that can withstand extremely high temperatures.

Ultrasound for improved crack detection

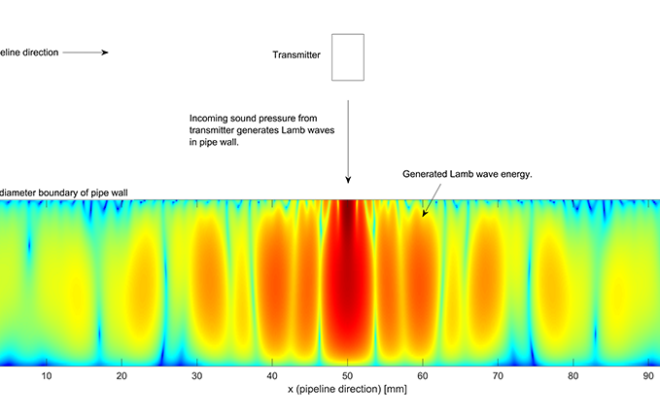

I have a created a modelling tool that can calculate ultrasonic sensitivity of cracks in pipelines, which is 8 times faster than commercial software. The model can simulate the behaviour and characteristics of waves within a pipe wall which are generated when an ultrasonic transmitter is radiating sound towards the pipe wall. These internal waves will be distorted somehow when encountering a crack, so knowing how these waves behave is vital in optimizing sensitivity in crack detection applications.