Detecting the smallest leakages without delay

Leaks in oil & gas boreholes can have serious consequences. But current monitoring methods have a significant information delay and are not very sensitive. This is why we have developed a new method that eliminates delay, and which can detect the smallest leakages.

Drilling of borewells through the earth’s crust is standard practice for extraction of oil & gas and, developing geothermal resources. It is also one of the long-term storage solutions for carbon capture and storage (CCS). The drilling process involves the circulation of a drilling fluid through the drilling assembly, into the borewell and back to the surface.

Variations in the geological formation mean there is a possibility of leakage of fluids between the borewell and the formation while drilling, and the processes are therefore carefully monitored and balanced. However, with deep borewells extending several kilometers subsurface, such leakages may take several minutes before they are detectable at the surface.

This delay in information means it takes longer to do something about the problem. A worst-case scenario is a “blowout” as seen above when the well is destroyed and the oil or gas leaks into the surrounding environment. In other words: an occupational, environmental, and economic disaster.

What can we learn from blood vessels?

The flow of drilling fluids in an oil & gas borewell has a lot in common with the flow of blood in the human body. Both involve a fluid being pumped through a convoluted network of pipes and tubes, and leakages can in both cases have catastrophic consequences.

State of the art medical ultrasound imaging systems can detect and quantify leaky blood flows through cardiac valves with great accuracy. Can we apply similar techniques to a seemingly similar problem in the oil & gas borewells?

Improved monitoring

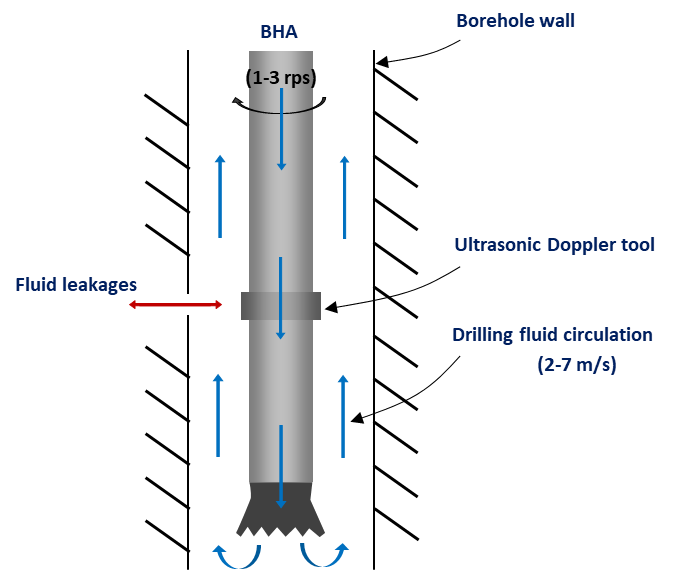

Our work is based on this possibility and explores the application of Doppler ultrasound for detection and imaging of leaks in the borewells. The imaging is done very close to the actual drilling site (at-bit); eliminating the information delay that potentially causes “blowouts”.

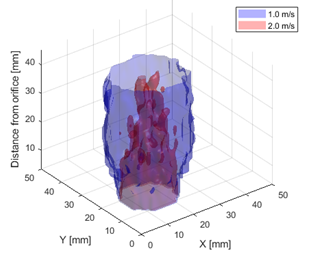

We explore the limits of existing ultrasonic logging tools used in the drilling assemblies, eliminating the need for any changes in existing instrumentation. The rotation of the drill bit in addition to varying vibrations from the drilling process pose significant challenges to Doppler imaging as it causes clutter in the signals. Despite these constraints, it is possible to reliably measure very small leakages (> 15ml/s) in the borehole wall using our method. In addition, it enables superior imaging resolution of the cracks compared to current methods.

Want to know more?

- You are invited to view our short 10-minute presentation on this topic for a more holistic understanding of our work.

- For those interested in even more technical details, please proceed to reading our article in the Journal of Petroleum Science and Engineering.