Crack-detecting waves

Whether they transport oil, gas, water, or other substances – you do not want them to leak. But if a pipe is in an inaccessible area, how do you then check for cracks? And if there are any – are they critical, or not?

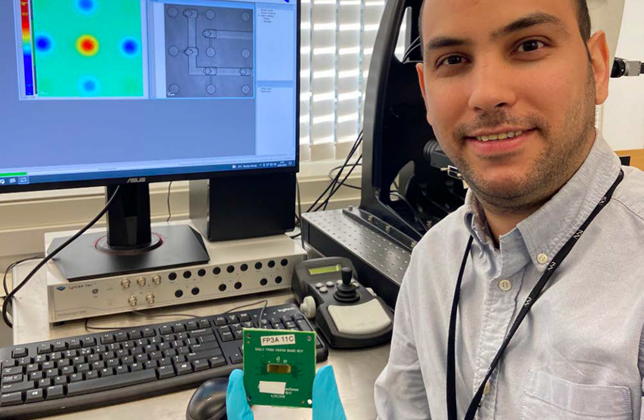

These are important questions for health and safety, and for the environment – especially in the oil and gas industry. Simen Hammervold Midtbø is now finalising his PhD on crack detection and assessment using Lamb waves and has already been employed by CIUS partner NDT Global, which specialises in ultrasonic and non-ultrasonic inspection of, amongst other things, pipelines.

How deep is the crack?

“The overall goal of crack detection technologies in pipelines is to find cracks of certain sizes and notify the pipeline operators of critical cracks. Critical cracks are defined by their shape and depth,” Midtbø explains. “A crack that is going through the entire pipe wall is very critical to detect, whereas a crack that is only 1% of the wall thickness is non-critical – though it would still be necessary to monitor that crack and its potential development.”

This is why crack depth is one of the more important variables that have to be accurately identified. Midtbø has chosen to use Lamb waves for this:

“The measurement of a Lamb wave that travels in a pipe wall will change if there is a crack in its path, and the change will vary with crack depth. However, this change can be subtle, depending on the measurement system and method, which can be modelled. This is where my work comes in, as I am working with a model that can be used for optimisation for such a measurement system to detect as much change as possible.”

Lamb waves modelling

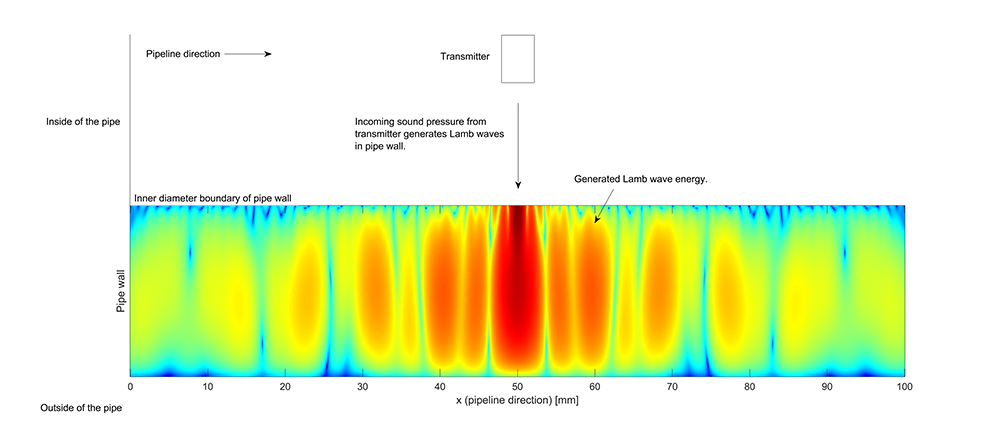

To create Lamb waves one can set a transmitter to radiate sound waves towards, for example, a metal plate – like a loudspeaker facing a wall. The sound waves will generate a Lamb wave inside the plate, and it travels along it. The wave energy can be measured using a receiver at a certain distance from the transmitter – a bit like placing a microphone along the plate a certain distance away from the loudspeaker.

If there is a crack between the transmitter and the receiver, the wave energy will change and can thereby be measured – in theory…

The size of the transmitter, the thickness of the plate, the distance between the transmitter and the receiver – they all affect the outcome. The proposed solution is therefore to use modelling:

“The first step of such a model is to develop a description that can account for a transmitter and plate, without cracks. This is described in my first PhD article “ASM and finite beam description of the excited leaky Lamb waves in a fluid-immersed plate” (Ultrasonics, 2022).

The second step is to perform measurements of cracks and use the model to analyse how the measurement-response is related to the different parameters, and how one can exploit that information to optimise the measurement system,” Midtbø says.

It may sound straight forward, but theories do not always correspond with the ‘real world’:

“The biggest challenge is perhaps being able to compare theory with measurements – or vice versa. Theory in physics/ acoustics are often limited by assumptions, so to understand what those assumptions mean for an actual, physical, real setup can sometimes be challenging,” he explains.

Already a fulltime employee

Midtbø is now in the process of finishing his second PhD article but has already started fulltime work for NDT Global. They are currently developing a crack detection tool, for which Midtbø’s expertise comes in useful.

Doing a PhD with an industrial partner has been a positive experience – also academically:

“As a researcher, I had access to tools and laboratory equipment necessary to do my studies. I was also fortunate enough to be stationed at NDT Global’s location in Bergen, so that I had an office and close contact with the technology, people, and challenges.

“Obviously this also put me in a good position when ending my time at CIUS and was offered a position within the research & development department at NDT Global,” Midtbø concludes.

Lamb waves

Lamb waves are waves generated within a thin layer of solid material such as a metal plate or pipe wall. They exhibit different properties depending on the material, but also depending on changes within that material – like cracks. The trick is to interpret the changing properties correctly – to correctly identify and measure cracks.

This article first appeared in the 2022 CIUS Annual Report.

- Kari Williamsonhttps://www.ntnu.no/blogger/cius/author/kari_williamson/

- Kari Williamsonhttps://www.ntnu.no/blogger/cius/author/kari_williamson/

- Kari Williamsonhttps://www.ntnu.no/blogger/cius/author/kari_williamson/

- Kari Williamsonhttps://www.ntnu.no/blogger/cius/author/kari_williamson/